Kirby Putt

Ever wondered why Inuit folk have so many words (52, according to anthropologist John Steckley) for snow? Because snow impacts the indigenous, Arctic existence disproportionately, every day of their lives. Course superintendents maintain a similarly co-dependent, etymological relationship with salt — which also goes by sodium, bicarbonate, NA, N-plus-plus, brine, alkali, sodium chloride, sulfate — for the same reasons.

Intellectually, superintendents recognize and appreciate that too much bicarbonate in soil can dangerously limit root growth by reducing plant access to calcium and other critical nutrients. It also binds up most soils, limiting porosity and access to oxygen. However, if high salt content in a soil profile stems from high pH irrigation water? Well, how many words do superintendents have for getting terminated?

“You have two things to worry about on a golf course: soil science and water quality,” says Kirby Putt, CGCS, the director of agronomy at Arizona Country Club in Phoenix. “I knew we had a problem with salt, on account of our water quality, but we sat on our hands. We had a guy come here from the University of Arizona a few years back. He needed a dowel rod to hammer in his soil sampler on my 10th fairway.

“Today, I could go out there right now and push one down 4 inches with my body weight.”

Three-plus years ago, Putt — a 30-year veteran of turf management in the desert, where irrigation water is notoriously poor; where sodium-rinsing rains are rare — first engaged with Todd Eden, owner of Scottsdale-based HCT, which markets uniquely prescriptive soil and water remediation services to golf course superintendents. Eden and HCT started out in the well world, mainly on behalf of municipalities. That’s how Putt was originally connected. “Our well guy said I should talk to them,” Putt says. “So right away he’s got some street cred.”

Because the water situation in Greater Phoenix is so sketchy, in terms of volume and quality, Eden had recognized HCT’s expertise and particular skill set might well benefit course superintendents. The firm now works with more than 220 separate golf facility clients. However, when Putt first encountered Eden, there were only two: down the road from ACC at The Wigwam Resort and municipal Papago Golf Club.

“So Todd comes over and he says, ‘How’d you like to be our third course?’” Putt says. “And I’m like, If this program’s so great, why isn’t everyone doing it? ‘Well, you superintendents are very particular. I want to show you where the problems arise and how we can cure them.’ And I’m like, Oh, this oughta be good. … Todd also said we were going to use a lot less wetting agents and fertilizer. Because all the guys say that! But we did start talking — about all the things we could do to remediate salt in our water and soil colloid.”

HCT serves soil, water and well clients via a brand called WaterSOLV, which provides proprietary chemical solutions that allow the sustainable treatment and remediation of water and, eventually, the soils absorbing that water. It’s a testing service that takes the next step: prescription. The company tests, then shares exhaustive water and soil analysis with clients, measuring total soil composition, available plant nutrition and nutritional needs. Its chemigation treatments are based around the injection of carefully calibrated doses of a proprietary blend containing hydrochloride in one and hydrogen peroxide in the other.

In short, HCT treats irrigation water that, in turn with more chemistry, remediates the soil.

“Let me tell you what HCT does not do,” Eden adds. “We don’t sell fertilizers, fungicides or pesticides, though fertilizer demand is defined by HCT’s matured analytical data. Our products do not remove golf-cart related compaction. HCT products are functional like acids and antiseptics. We sell through authorized, qualified dealers. Our job is making water, soil and nutrition more available for plant uptake, which naturally leads to lower sodium percentages, increased pore space, vegetation optimization, lowered costs and a more substantial ROI.”

Claims of ROI typically doom vendors when dealing with golf course superintendents, who’ve heard it all before, and for whom healthy vegetation is reward enough. Yet Putt is among a growing cadre of superintendents who’ve bought in. Though not because, as Putt points out, his annual sod budget dropped from $36,000 to $2,500 last year.

“On one level, this is very technical stuff,” Putt says. “I was like, ‘Todd: I don’t get it. I’m not a scientist. I had the classes way back when, but I’m not breaking down molecules on a blackboard.’ I also thought he was just looking for another high-profile property to make the case for this product. But I did go to Papago and The Wigwam, to talk with the supers there. More street cred. That’s how we got started: a little bit of blind faith on my part to help the salinity and scaling that takes place in my soil.

“I do use the product, have for over three years now, maybe four. I don’t get anything for promoting Todd and his products. Zero. But we’ve found that it’s a nice addition to our agronomic program. Scientifically, I can’t fully explain what’s going on, but it seems to be working from a compaction angle. I strongly feel it has released tied-up nutrients in the soil, as I did not fertilize the (treated) roughs for over nine months based on growing conditions and color.”

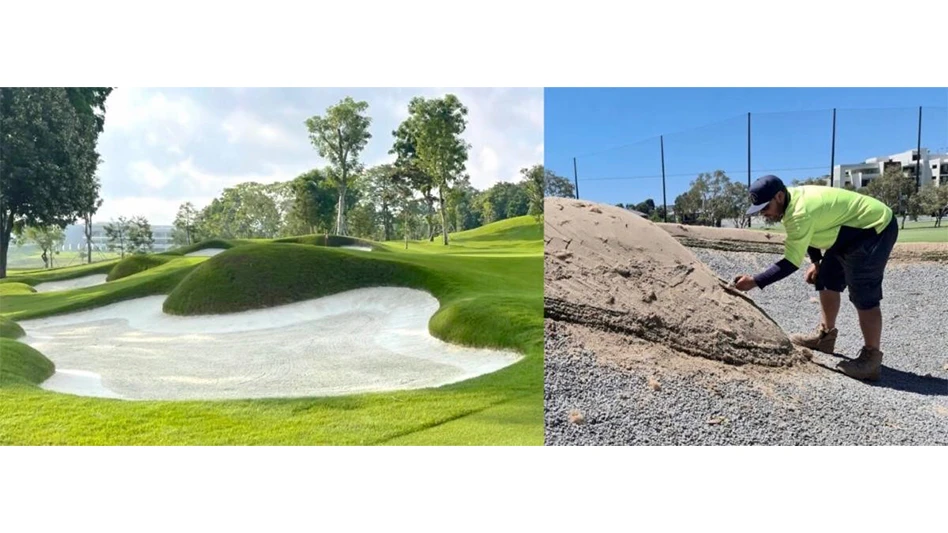

(Courtesy of HCT)

(Courtesy of HCT)

Those rough areas at Arizona CC were the first step, Putt’s first test plots, if you will. The HCT testing showed undesirable buildup of sulfuric acids, salts and mass amounts of fertilizers in the soil colloid. That in itself, according to Putt, is enough to “block things up.” Eden recommended a WaterSOLV treatment at four gallons per million gallons of water, continuously injected.

“I knew we had to do something,” Putt recalls. “We were throwing gypsum on there. So I knew we had calcium in the soil, but I couldn’t get it to work for me. In the end, I was willing to take the 6-grand risk.

“There was nothing like a nirvana moment. After a while, though, the roughs start holding their color, where they usually don’t. I said to myself, I’m not going to fertilize the rough till I see them go yellow. Well, I didn’t fertilize for nine months! I also noticed more uniformity. Some of the typical bad spots in the same rough areas were not as bad. And yes, I could finally push a soil probe down in there without a hammer.”

A year goes by. Then ACC received an inch of rain overnight.

“That’s something that causes big problems here in the desert,” Putt says. “But I’m noticing my wet and dry spots are not so prominent. Where’d that inch of water go? So, I called Todd and asked him. He looked at our numbers and said, ‘We need to back off a bit. We’re opening things up in there.’ The fact that we were only using four ppm, and we reduced it to two ppm, was evidence that something was working. We also injected the hydrogen peroxide product at .5 ppm, adding another oxygen molecule to the soil. That’s been good for breaking up black layer. It kills bad bacteria. You put hydrogen peroxide on a wound; it works the same way in soil.

“But Todd’s recommendation really resonated with me because, honestly, whoever tells you to use less of anything in this industry? Ultimately, once I gave it a shot, we have continued to use it on a maintenance level, which doesn’t cost that much and the results continue to be positive.”

Kirby Putt

Putt wasn’t born to the desert and its poor water quality. He grew up in Pennsylvania, earning his turf degree at Penn State before moving out to Tucson in 1986. He landed the top job at ACC in 1988. After seven years, he relocated back to Greater Philly, where he managed some courses and tried his hand at being a general manager. After 11 years, ACC called him back. He couldn’t say no.

That first stint at the club, in the 1980s, informed his willingness to take chances, to try some things — even if it didn’t always work out.

“The big issue is changing the water without inhibiting anything else, or creating other problems in the soil,” he says. “Like sulfur burners: We all sprayed sulfuric acid out here in the 1980s. We’re still shaking our heads about that. We didn’t know any better. Todd is onto something very different and way better: He’s found a way to safely and cost-effectively create a better growing medium for turfgrass. We have bicarbonates and alkali in our soil and high pH in our water. These (WaterSOLV) treatments are getting sodium out of the way.”

Putt deploys some pretty creative metaphors for this sodium-neutralization process. In its literature, HCT prefers the more sober ‘detoxification’ of sodium, the ‘sequestering’ of minerals, and the ‘deterrence’ of anoxic bacteria and their exudates. But what fun is that?

“Because pipes corrode or get smaller or more narrow over time, you have to clean them out. We’re doing that to our soil,” Putt explains. “If you have Na plus-plus, sodium is like a bully at the gym. He says, ‘Get off the bench press.’ He kicks all the calcium out. We’ve kicked sodium off the machine. Now, as a result, all the other stuff is available to the plant roots. That’s why I didn’t need to fertilize my rough (after the trial application), because those nutrients, which we knew were there, were finally made available to the plant.

“Our water is high in pH. If you don’t have a neutral tank of water, there are certain products you spray on a golf course and they just won’t be as effective. Insecticides are a good example: If your water hasn’t been treated to lower the pH, you get three days from an insecticide spray — not the 30 you’re supposed to. HCT has figured out how to help that cause by treating the issue at the source, the pH in the water.”

Ultimately, according to Putt and Eden, the sequestering of all these harmful elements, the remediation of things like high pH, ultimately adds something important to treated soils: dissolved oxygen.

“When your water is bad, things get mucky,” Putt says. “Since bringing down our pH, our soils are more open and oxygenated. They’re looser. There’s more porosity. Of course, compaction and tighter soils cause shallow rooting. It’s just another way roots can’t get to the water or nutrients they need. Plants like that die much faster in a drought situation. As grass growers, we want roots going down as far as possible, and that’s what Todd is helping us do here. We still aerify and topdress the same as we always have. Coupled with this product, we are achieving our goals.”

Hal Phillips is a Maine-based freelance writer, managing director of Mandarin Media, Inc., and former editor-in-chief of Golf Course News.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

Latest from Golf Course Industry

- Toro continues support of National Mayor’s Challenge for Water Conservation

- A different kind of long distance

- Golf Construction Conversations: Stephen Hope

- EnP welcomes new sales manager

- DLF opening centers in Oregon, Ontario

- Buffalo Turbine unveils battery-powered debris blower

- Beyond the Page 66: Keep looking up

- SePRO hires new technical specialist