Getting the job done faster on greens is probably the greatest advantage of triplex mowers. They offer golf courses increased productivity and a quality cut.

Designed to be lightweight and maneuverable, the versatile triplex mower also is the choice of many superintendents for tees, approaches and fairways.

Toro trim-mower technology

In 1999, Toro introduced the first triplex trim mower with the patented Sidewinder cutting system, according to the company. Since then, trim mower technology has helped superintendents reduce labor, control costs and achieve a high quality of cut with reel and rotary trim mowers.

Producing a skillfully manicured golf course requires looking at all aspects of mowing.

"There’s a distinction between quality of cut and the after cut appearance," says Tony Ferguson, Toro’s marketing manager for Reelmasters. "Many people think they’re synonymous, but they’re really two different things. Quality of cut is how well you’re cutting the grass as you’re cutting it. The after-cut appearance is what it looks like when you’re done. Is it uniform? Is there overlap? Is it cleanly cut?"

Quality of cut and after cut appearance are important to golf course superintendents because both impact the aesthetics and playability of a golf course. And although these two terms can sometimes overlap, Toro considers quality of cut and after-cut appearance separately when designing and testing mowers.

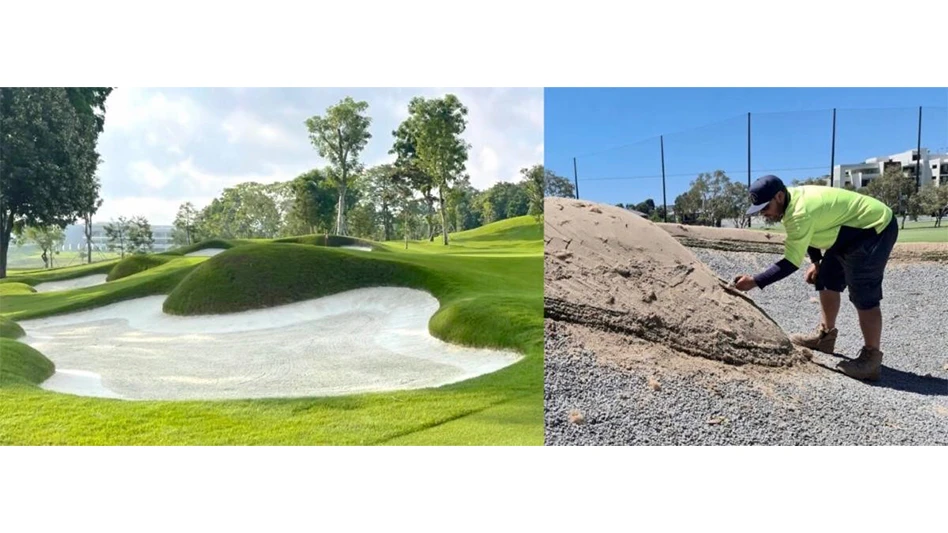

Superintendents typically use trim mowers for trimming surrounds around bunkers, greens and  sometimes even small rough areas, according to Kevin Conry, marketing manager for the Groundmaster product line.

sometimes even small rough areas, according to Kevin Conry, marketing manager for the Groundmaster product line.

"Our rotary trim mowers essentially have made it possible to mow trim at higher heights of cut where rotary mowers thrive," Conry says. "Toro rotary trim mowers are equipped to handle undulations commonly found around bunkers and surrounds because each 27-inch deck floats independently. This quality of cut from a rotary changed how many courses managed their trim areas."

The Toro Groundsmaster 3500-D, which Conry refers to, is a riding trim rotary mower with a 35-hp turbo-charged engine and free-floating rotary decks, which can be shifted 24 inches right and left with the Sidewinder feature.

"The Sidewinder provides a lot of versatility because the traction unit doesn’t have to operate as close to a lake or bunker edge," Conry says. "The decks can be shifted from day to day so the tires aren’t driving over the same track. That means less compaction and turf damage."

The Sidewinder feature also is available on the Toro Reelmaster 3100-D for trim applications.

"The Reelmaster 3100-D has cutting unit options that provide either a 72-inch or 85-inch width of cut," Ferguson says. "For those that need a narrower unit to maneuver around obstacles or a wider unit for maximum productivity, Toro has it."

Additionally, the Reelmaster 3100-D features a distinctive operator-out-front design and Series/Parallel 3-wheel drive traction system, which minimizes spin-outs.

"It has superior traction capabilities on hilly and wet turf conditions," Ferguson says. "You would actually have to spin one of the front wheels and the rear wheel at the same time to get stuck. That’s pretty tough to do. This prevents scuffing the turf as well."

Using agile triplex mowers for trimming also can offer productivity gains and corresponding labor savings.

"One course in particular replaced their hand mowing entirely with a Reelmaster 3100-D by justifying the labor cost savings," Ferguson says. "That’s not going to be true for everyone, due to slopes that are too severe, but in many cases, courses are finding that they can replace some or all of their hand and fly mowing operations, thereby saving time and money."

Another benefit the reel and rotary trim mowers provide is an attractive after cut striping pattern.

"With the rear rollers you have an aesthetic benefit that you usually wouldn’t get with a standard rotary," Conry says about the Groundsmaster 3500-D.

Conry boils the key features of the mowers down to three things.

"The most important attribute is the ability to follow the ground undulations because they give you a good quality of cut without scalping," he says. "The second would be the Sidewinder feature because it allows you to reach into places more safely and get close to obstacles without endangering the operator. The third point would be the after-cut appearance you get with the striping rear roller. Toro trim mowers provide the versatility superintendents need to create attractive playing surfaces at the desired height of cut while reducing labor and saving time."

John Deere’s 2500A offers ease of operation, service

Designed for ease of operation and service, the quality of cut achieved with John Deere’s 2500A triplex greens mower is enhanced by a new cutting unit suspension that carries the weight of the lift arms on the traction unit and not on the cutting units. This is critical on daily cleanup passes because the mower can move clockwise one day and counterclockwise the next, so the wheel pattern won’t be in the same track. This greatly reduces the triplex ring associated with this operation.

The 22-inch cutting units are designed and manufactured by John Deere and come with 11-blade reels, 3-mm standard bedknives and a smooth or grooved front roller. The cutting units also feature a new bedknife-to-reel design.

In addition, the command arm puts the key switch, mow switch, throttle lever and raise/lower lever  conveniently at the operator’s fingertips. The mower also features tilt steering and a two-foot-pedal system for forward and reverse. Features of the 2500A include:

conveniently at the operator’s fingertips. The mower also features tilt steering and a two-foot-pedal system for forward and reverse. Features of the 2500A include:

• 19.9 hp (gross) /18 hp (net), three-cylinder, liquid-cooled diesel engine;

• Patented offset cutting units and cutting-unit suspension to minimize perimeter compaction and turf wear;

• Low-profile tires with a wide footprint;

• Ergonomic control arm and operator station for operator comfort, visibility and easy operation;

• 22-inch cutting units with bedknife-to-reel design for ease of service;

• Grass catchers designed for optimum catching efficiency and improved cut quality;

• Standard hydraulic oil cooler for improved hydraulic system performance and durability;

• Sit-on-seat diagnostics to improve serviceability and diagnostics;

• Tilt-back hood and tilt-up seat platform provide good visibility to components;

• All daily service checks are made from the left side of the machine; and

• High-strength, tubular steel frame provides increased strength and improved rear cutting unit visibility.

National Mower’s 68 Deluxe has 7-mph transport speed

National Mower’s 68 Deluxe triplex mower can increase productivity with its 7-mph transport speed. An out-front steering system allows the mower to go almost anywhere.

It has a 68-inch cutting width and 21-inch wing mowers that follow severe contours. The reel mower provides a cleaner cut and better appearance than a rotary mower, according to the company. The tooled-steel reel blades and bedknife are built to last twice as long as others do on the market.

The compact and lightweight design lets the mower maneuver through tight places and allows mowing in soft areas with minimal tracking. A large reel overhang makes for better trimming capabilities.

There’s no shroud over the engine, which provides good airflow to the engine and easy access for  maintenance. The mower’s mechanical drive requires less horsepower for operation and reduces maintenance. Parts are readily available and inexpensive to replace.

maintenance. The mower’s mechanical drive requires less horsepower for operation and reduces maintenance. Parts are readily available and inexpensive to replace.

An electric starting system makes starting and stopping easier when an operator needs to pause for golfers.

The 68 Deluxe triplex mower tractor is powered by an electric start 7½ hp Briggs & Stratton four-cycle engine. It has a welded tubular steel frame; hardened steel gears and clutches for traction, and the wing and rear mowers. The differential is automotive-type. Steering is tie rod and drag link, and it features full pneumatic, power grip tires (front, 350 x 6; rear, 650 x 8).

The mowers include two 21-inch side wings and one 30-inch rear free floating for a total 68-inch width of cut. Reels feature six blades, inches thick and

inches wide. The seven-inch diameter reels adjust down to a high carbon steel bed knife with a -inch lip for longer life. Timken reel bearings disengage the mowers for transport.

Jacobsen’s Greens King VI

The Jacobsen Greens King VI is versatile, reliable and a user-friendly triplex mower, according to the company. Whether maintaining greens, tees, approaches or fairways, the triplex mower has the ability to deliver results that meet golf course superintendents’ high expectations.

The mower features a 62-inch cut. The fully floating, steerable cutting units help prevent marking and scuffing while turning. There are 11- or seven-blade reels for a high-quality finish in a variety of turf conditions. The mower has other features and benefits:

• Engine offerings include a liquid-cooled, fuel-efficient 19-hp Kubota diesel, or an 18-hp Briggs & Stratton gas engine;

• The mower offers pedal and joystick control, along with a padded, adjustable steering wheel;

• Attachments include vertical mowers, spikers, brushes greens roller and patented turf groomer. The groomer doesn’t extend the roller base and that keeps the rollers closer together to minimize scalping;

• Grooved and smooth rollers;

• Backlap optional;

• A one-touch lift/lower system features an electronic solenoid valve coupled to a sophisticated electrical system. Roller sequencing is automatic, unlike other mower models that use a mechanical system;

• Motor and hydraulic fittings are mounted outside the frame, allowing easy access;

• As part of the hydraulic circuitry, steel lines have replaced rubber lines in the chassis;

• A redesigned hood opens from the back for better access; and

• Biodegradable hydraulic fluid is available.

Oakmont (Pa.) Country Club acquired a number of Greens King VI units throughout the past few years. The club’s superintendent, John Zimmers, says the mowers are quite flexible.

"Our fairway mowing technique is a little different," Zimmers says. "Operators who only cut straight lines use grooved rollers. Operators who mow around the edges on their cleanup pass have units with solid rollers. With the Greens King VI and the FlashAttach system, we can swap heads quickly. Plus, if we want to use different attachments for greens, tees or other areas we can make the changes quickly and easily. We have a lot of flexibility with this mower."

Zimmers says the golf course has changed since it started using the units.

"Comments from members have been unbelievable," he says. "They say the condition of the fairways is much improved. The reasons are the quality of cut and the fact that the Greens King VI is a lightweight machine. We’re able to mow more often because of its lighter weight and the three-wheel-drive feature. Before we got these units, we couldn’t get out on wet days with heavier mowers."

Small features on the mower mean a lot to Zimmers.

"An adjustable steering wheel is more important than someone might think," he says. "Every operator is different, and if you want them to go out and do their best, you have to provide them with comfort features."

Zimmers says the joystick control option is a big plus.

"Some people always use their feet, while for others their hand-eye coordination is better, and they prefer the joystick," he says. "I like the flexibility of it because in summer when we bring in students and interns it’s nice for them to have the option of using either their feet or hands. That may sound farfetched, but it’s true." GCN

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

Explore the June 2004 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- Toro continues support of National Mayor’s Challenge for Water Conservation

- A different kind of long distance

- Golf Construction Conversations: Stephen Hope

- EnP welcomes new sales manager

- DLF opening centers in Oregon, Ontario

- Buffalo Turbine unveils battery-powered debris blower

- Beyond the Page 66: Keep looking up

- SePRO hires new technical specialist