When I go out onto golf courses to do evaluations and designs, one of the questions I like to ask the maintenance staff is how many mainline and lateral breaks they have had in the last year and the last five years. Basically, I am breaking – pardon the pun – the question down into big pipe and little pipe. The answers give me an idea of how well the piping system is holding up and if it can be reused, if the hydraulics are any good, and an indication of how well the pipe system was installed. I also ask what kind of breaks they were. You would be amazed at how many times the reply to the second question is that it was a leak in a previous repair or as the industry likes to say: “a repair of a repair.”

Many times, and not just on golf courses, irrigation repairs tend to be reactive. That is, the fix is made when it is discovered and made as quickly and as easily as possible. As a result, many of the repairs do not last and end up having to be dealt with later, many times by different staff so they do not learn from their mistakes. A recent golf course I visited had made 80 lateral repairs in the last few years with over half of them being previous repairs.

Quality training, determining what caused the break and using proper materials are keys to not making repairs of repairs.

Training

Make sure your staff is properly trained in solvent weld cementing techniques, thrust blocking and pipe preparation. Many people think that solvent weld cementing, aka gluing, is straightforward and anyone one can do it, but the manufacturer will tell you there is a process to solvent weld cementing and if you do not follow the process, the joint can/will fail over time. PVC joints commonly fail 10 to 15 years after installation due to poor solvent weld cementing techniques, often due to the use of too much primer or cement.

Cause

This is the most difficult aspect of the repair process. What caused the pipe or fitting to fail in the first place? If someone put a backhoe bucket through it, the cause is obvious, otherwise it might take some investigation. Pipe and fitting breaks can be caused by high pressure, surge pressure, poor cementing procedures, poor thrust blocking, or bad pipe or fittings. These issues could be the result of poor design or bad installation practices, but they could also be operations. If you operate too many sprinklers in the same area and do not spread out the water, you raise the velocity in the pipes and therefore water hammer/surge pressures. Thrust blocks also can fail if not properly installed. The thrust block needs to be properly sized and always installed against undisturbed soil. In soft soils, the thrust block needs to be stabilized.

Materials

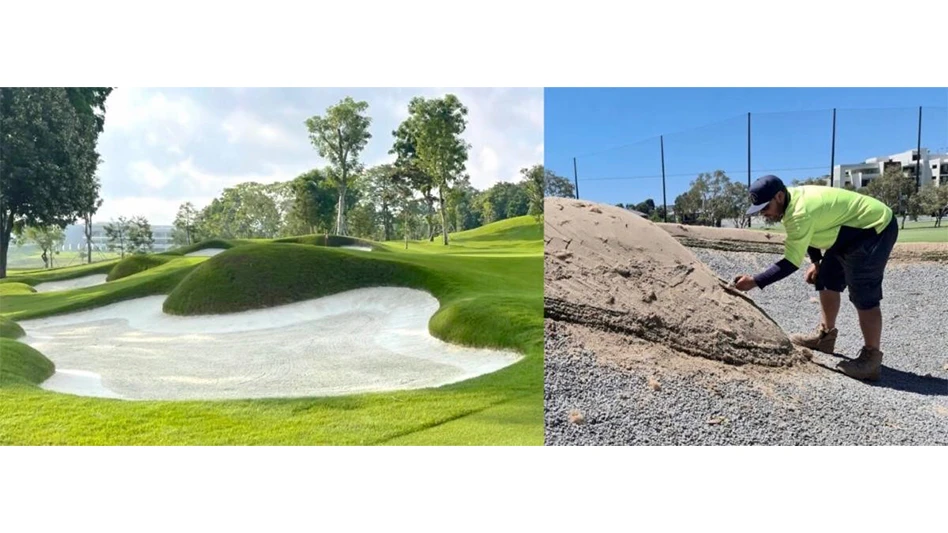

Material selection depends on what type and size of pipe or fitting failed/broke. For small pipe, 2½-inch and below, many people use telescoping repair couplings. Between the ability of the coupling to move after installation and having two solvent weld cement joints they usually do not last long. Compression couplings are a better choice, but the connection needs to be pretty straight and your process flawless or it will slip over time. In the picture, the pipe was not properly aligned and the compression coupling repair failed. The threads on the compression couplings do not like any dirt in them. A knock-on PVC or ductile iron coupling is usually a better choice. For larger pipe, 3 inches and above, you can also use compression couplings, but they have the same issues as with smaller pipe.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

Explore the August 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- Bloom Golf Partners adds HR expert

- Seeking sustainability in Vietnam

- Kerns featured in Envu root diseases webinar

- Toro continues support of National Mayor’s Challenge for Water Conservation

- A different kind of long distance

- Golf Construction Conversations: Stephen Hope

- EnP welcomes new sales manager

- DLF opening centers in Oregon, Ontario