Underground rake caddie

• Reduces cost of moving bunker rakes by maintenance crews so traps can be raked and the grass mowed

• Doesn’t interfere with play and is aesthetically pleasing

• Maintained underground out of the way of maintenance crews

• Keeps the rake clean and dry

• Push lid to open, and rake pops out of the ground about 24 inches

• After use, golfer puts rake back into caddie and pushes it down with a golf club until the rake locks in place; then golfer kicks the lid shut and the rake is out of the way

• Rake handle won’t erode in the sun

• Spaced no more than every 16 yards around the bunker

Underground Rake Caddie

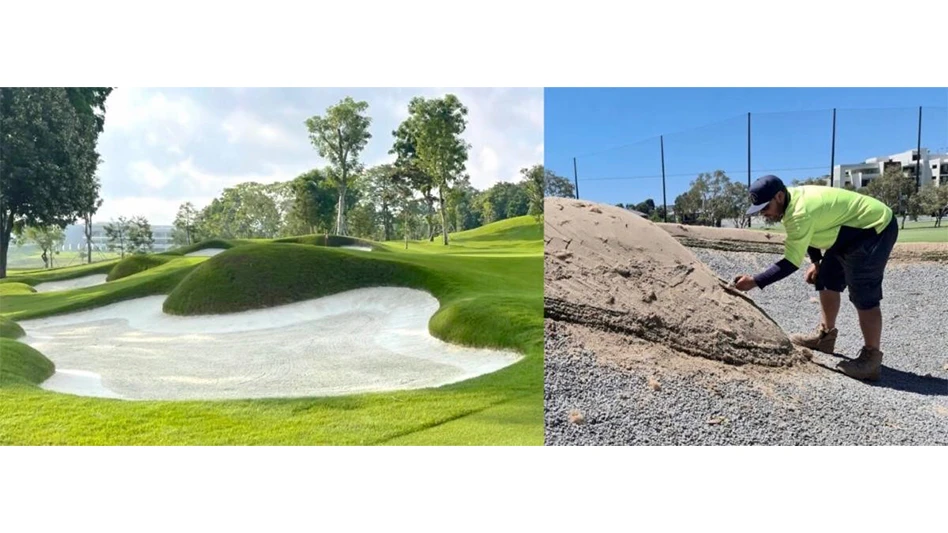

Drainage system

• Composed of three layers: an impervious liner membrane, a unique ring and grid system, and a geotextile that are covered with bunker sand

• Installation can be fast, resulting in drainage beneath every square inch of bunker surface with a void space for the circulation of air and excess water

• Sand can’t infiltrate the fabric, while water flows freely, preventing clogged drainage and water collection in and above the sand layer

Airfield Systems

Bunker pumper

• Pumping rate capability of 240 gpm

• 6-hp Briggs & Stratton engine

• Triple protection grease-filled seal prevents water and debris from coming into contact with engine components

• Floating pump weighs less than 90 pounds and is used for draining pools, sand traps, construction ditches and low-lying field areas

• Self-priming and can be operated at full throttle for about 45 minutes on one tank of fuel and can run dry with no harm to the engine

• Centrifugal pump offers submerged suction without additional hoses or priming systems

• Can operate in less than 3 inches of water

• Removable float makes it easier to handle, maneuver and store

• One-year limited warranty on the entire unit

Otterbine Barebo

Sandmat geosynthetic bunker liner

• Combines manufacturing, geotechnical and geosynthetics expertise for improved bunker management techniques

• Engineered blend of high tenacity polyester fibers bonded to form a thick blanket-like matrix designed to enhance bunker drainage, minimize sand washouts, prevent infiltration of contaminating fine or coarse subgrade particles and improve course aesthetics and playability

• Available directly from the manufacturer and locally through a national network of regional representative organizations

Western Nonwovens

Sandstorm screen

• Lightweight mobile unit enables removal of undesirables from bunkers

• Remixing the different sieve sizes renews bunkers’ ability to rid itself of excess moisture by allowing the water, formerly trapped by compaction, to get to the drainage system

• Powered by a 12-volt DC vibratory motor

• Provides the ability to revive bunkers’ current status and maintain them

Z Screen

Explore the June 2004 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- Toro continues support of National Mayor’s Challenge for Water Conservation

- A different kind of long distance

- Golf Construction Conversations: Stephen Hope

- EnP welcomes new sales manager

- DLF opening centers in Oregon, Ontario

- Buffalo Turbine unveils battery-powered debris blower

- Beyond the Page 66: Keep looking up

- SePRO hires new technical specialist