Building the final course of a six-course golf facility in the Arizona desert posed several challenges for SEMA Golf, especially when the company never worked with Nicklaus Design before. But despite the challenges, SEMA Golf successfully completed The Outlaw at Desert Mountain course to the satisfaction of its owner, Desert Mountain Properties, and won the 2005 Golf Course News Creative Award for best new construction project.

|

“You’re only as good as the last course you build,” Steele says. “We’ve built 150 golf courses. It’s a real relationship business with architects and owners. We had never worked with Nicklaus Design, but I knew all the players there. I’ve been in this industry for 30 years. I have contacts, and people know what I’ve done in the past.”

Bob Jones, senior v.p. of Desert Mountain and Cresent Real Estate Equities, says the company wanted to add another golf course to Desert Mountain, creating one with a unique draw for members.

“Looking at the topography and meeting with Jack (Nicklaus) and Lyle Anderson (a partner with Desert Mountain), the land dictated a links-style course that would be unusual for Desert Mountain,” Jones says. “And because of the reclaimed water line under the course, we were allowed to put up 110 acres of grass.”

Shawn Emerson, director of agronomy at Desert Mountain, was involved in the planning of The Outlaw course from day one. Emerson says a project manager was hired for the golf course, then a construction superintendent was hired to manage the course.

|

Shapes of things

Tom Soileau, who was the on-site architect for the Outlaw project and who hadn’t worked on the other courses at Desert Mountain, says the golf course sits on a sloping site that featured a series of ridges and valleys with vegetation.

“The site was narrow, and that was the reason why the course was laid out the way it was,” Soileau says. “We wanted some holes to run up and down the valley, but we ended up going perpendicular to the slope.”

|

But the main concern was that the 190-acre site was narrow and small, which dictated a precise routing plan.

“The property was long and had a cross slope to the east, and we needed to make it look natural,” Steele says. “Jack didn’t want us to disturb the green spaces and wanted the greens to sit next to the hillsides. He wanted a Scottish-style golf course. There were a huge variety of things that he wanted to fit in.

“Having an on-site coordinator from Nicklaus Design was key to the success of the project,” he adds. “If something wasn’t working right, he could sketch something and send it to Jack.”

Water delay

Another challenge the developer faced was waiting for water to be delivered to the site from the city. The owners were dependent on the city bringing the water lines about 12 miles to the course. The city had to go through rock and was behind schedule, according to Steele.

“We were at the mercy of the city,” he says. “When we found out the city was two months behind, we had a temporary water line to flush the irrigation system while waiting for the real water. We couldn’t have pulled it off if everyone wasn’t a team player.”

“When the project got stalled because of the water line, SEMA worked on finishing other aspects of the course that didn’t need irrigation,” Jones says.

And the grassing philosophy changed because of the water delay.

“We were originally going to sprig the course, but we ended up sodding the course with 419 Bermudagrass,” Emerson says. “We got 60 to 70 acres of sod from West Coast Turf. We built all of the green complexes first, then sodded around the greens, then seeded the greens with Dominant bentgrass.

“We wanted 120 days from seeding the greens to opening day,” he adds. “We seeded in June and opened in November in 100-degree heat. It took great coordination. We wanted to sprig the course because of a $10,000 to $12,000 cost difference per acre. We wanted to save on water, fertilizer and labor. There is less wear and tear on equipment when you sprig a course. Originally, we thought we could open up 30 days sooner. But it ended up being a wash because we got the course done on time.”

The Outlaw at Desert Mountain |

Location: Scottsdale, Ariz. |

The development of the course was precise, and Emerson says a group of six holes had to be completely finished before moving on to the next group of holes.

“We didn’t have time to go back and do a punch list once the entire project was finished,” he says. “The last thing we did on each hole was sod. The key was finishing the holes completely. While doing the next six holes, we went back and did a punch list on the previous six. Change orders kill golf course construction. This project had very few.”

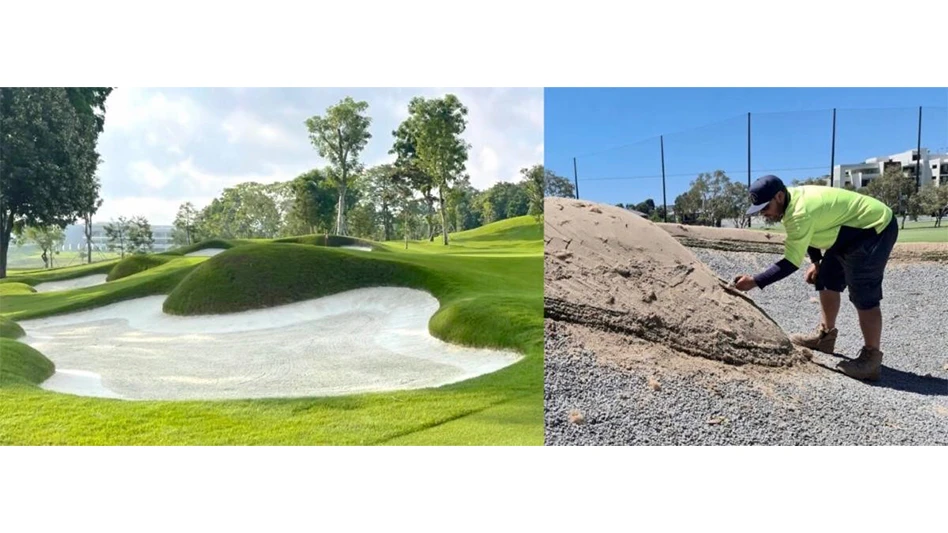

Sand capping

Sand importation to site was another challenge. Sand was used to cap the entire golf course at an average of six inches. Product location, scheduling and implementation were instrumental in bringing this together. The sand capping was done on time and on budget by continual monitoring and management by the team, according to Steele. This included delivery, scheduling, job-site access and timely proper application of the sand capping.

Working as one

Steele, Jones, Emerson and Soileau agreed teamwork and communication made the project successful. The only change orders generated for construction were for work due to delays in water availability, all of which were generated or amended to the contract by the owner, Steele says.

“We met weekly during the project and went over all of the changes,” Jones says. “SEMA’s reports were timely, and they had our interests first. We found that Bob had contractual numbers given, and when we wanted to move things a bit, those were done without change orders. He didn’t have the, ‘If you want me to do this, I’ll have to create a change order’ attitude.”

And SEMA was not the low bidder on the project, according to Jones.

“We have learned that cheaper is not always better,” he says.

The scope and cost of the job was bigger than what the company originally planned for, but the design dictated that, Jones says, adding that SEMA was attentive and worked with the owner to not increase the cost of the project.

“This is probably the most complete golf course (including landscaping and cart paths) we’ve done,” Jones. “We did a weekly sign-off on the aspects of the course. It took a unique architect and construction group to pull this off.”

Jones says he had met with Steele previously and had gotten to know him.

“I had him look at some smaller projects in the past, and I saw his personal attention to detail. He let me know he didn’t like taking on too many golf course projects because he wanted to focus on them. His personal oversight made the difference.”

Soileau says working with Lyle Anderson and the people at Desert Mountain was great.

“They are very professional,” he says. “I have been used to doing that type of quality work for Jack for 10 years. We had assembled a really good team: the owners, contractors and architect. Everyone worked toward a common goal. We really worked as one.”

The course was expected to have PGA conditions the first day, Emerson says.

“There was a lot of pressure on the project manager and contractor,” he says. “It was the best finish job I’ve ever seen on a golf course. The punch list was finished in less than a week. If we didn’t do something right, then we did it over again right there.

“The key to the project was communication and the weekly meetings we had,” he adds. “Everything was done in the best interest of the golf course, which was the priority, not money or anything else. I could have played any one of the PGA or LPGA events on the course the opening day. It looks like it’s been here for years. It doesn’t look new. The clubhouse and maintenance facility opened the same day as the course.”

Steele says SEMA was always under a microscope because the owner expected perfection and says the project helped SEMA go to the next level.

“We stayed within our budget,” he says. “There were very little change orders because of all the project coordination’s weekly meetings. It boils down to communication and knowing what they wanted upfront. To me it’s one of the top golf courses we’ve built. It’s one of the nicest golf communities we’ve been involved with. Desert Mountain is the only golf community with six courses worldwide with such high standards. It’s great to have this on your resume. GCN

Quotes from the judges |

“Across the board, SEMA had the highest recommendations that were credible from the owner, superintendent and the architect, who is well known as difficult to please. They quantified the cost-benefit ratio – only $5,000 in post construction work, whereas the other builders said there was minimal or some.” – Jeff Brauer, golf course architect and president of GolfScapes |

Explore the March 2005 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- Toro continues support of National Mayor’s Challenge for Water Conservation

- A different kind of long distance

- Golf Construction Conversations: Stephen Hope

- EnP welcomes new sales manager

- DLF opening centers in Oregon, Ontario

- Buffalo Turbine unveils battery-powered debris blower

- Beyond the Page 66: Keep looking up

- SePRO hires new technical specialist