This past winter someone at our Wisconsin Turfgrass Research Day asked if I had received a certain text.

“No,” I replied. “I neither send nor receive texts.” He accused me of being a liar.

“Emails? Yes. Texts, tweets, Facebook and whatever else there is – no.” That small incident got me to thinking about all the technology that surrounds us, and when I first embraced it. I was taking a grad school class in quantitative chemistry, and each lecture included some extensive problem sets which involved a fair amount of math. I spent too much of my time doing those math problems “long hand.” Finally, my wife and I agreed I absolutely had to have a slide rule. We were poorer than church mice, so I went to the University of Wisconsin Credit Union, applied for a loan, and was granted it. The loan was the first of my life.

I took my $35 loan (honest – it was a $35 loan) and bought a slide rule. It was the best purchase of my life to that point and made my academic life enjoyable again. This event clearly demonstrates that I am not averse to technology and devices and machines that make our lives easier.

But sometimes high technology comes at a cost too high, I think. Simple jobs are actually made more difficult or more frustrating, and when the technology doesn’t work, simple tasks can become impossible. Circumstances like these make a guy look back fondly to simpler times.

The summer before I was drafted into the Army I attended the first Jacobsen School for College Turf Students. The highlight was our introduction to Jake’s prototype triplex greensmower. The wave of new technology, available after two years in the service, was that greensmower, a Toro bunker rake that was vastly superior to the Stan Clarke rake and automatic irrigation systems.

Rotary mowers have replaced reel mowers for most rough areas, and hydraulic units have replaced pull frame mowers for fairways and other golf course features. Large area hydraulic aerifiers have replaced Ryan Renovaires for fairway aerification and done a better job in a fraction of the time.

And if you really want to gauge how much technological progress golf courses have seen, look at what’s available in irrigation equipment, controllers and pump stations. The plant sciences have profited tremendously from improvements in seed technology, pesticides and plant nutrition. Golf course conditions are better because of them.

However, I am suggesting that sometimes high technology goes too far, and an occasional return to time proven practices, procedures and equipment of past years can actually be progress. That is why superintendents often hand rake bunkers for big tournaments, and explains why many greens are cut by walking mowers, not triplexes. There is a reason it is called “hand-watering;” sometimes syringing with a 1-inch hose and a flattened pipe nozzle does the best job.

Sometimes it is exhausting to listen to someone asking over and over, “Where’s my phone?” Or to walk into a shop lunchroom at noon and experience silence, not because the crew is eating or reading the paper. They are all on their phones. Gone are the days, I guess, when noontime meant conversation, a few hands of cards or a long-running trivial pursuit game.

Maybe the difference between low technology and high technology defines the difference between the art of greenkeeping and the science of contemporary golf turf management. It is likely the best golf course operations are a blend of both. At least that is what I would like to think. I wouldn’t want to return to the days of yesteryear. Times change, and as the old saw goes, you have to keep up with those changing times.

One of the highlights of my life came during the 2015 PGA Championship at Whistling Straits. Michael Lee, manager of the four Kohler golf courses, arranged for me to lead a parade of staff and equipment from the shop yard to the south end of the golf course where play had cleared and preparations for the next day could begin. I led this parade of the latest in golf turf equipment down a county road driving a Toro General tractor, the same one that we had in our shop for my entire career. He rescued it and I got to drive it that day. I loved listening to that six-cylinder Continental engine with its overhead valves purring along the entire way. What a thrill.

It was sentimental, have no doubt. But it also confirmed that a 60-plus year old tractor driven by a 70-year-old guy can still be useful.

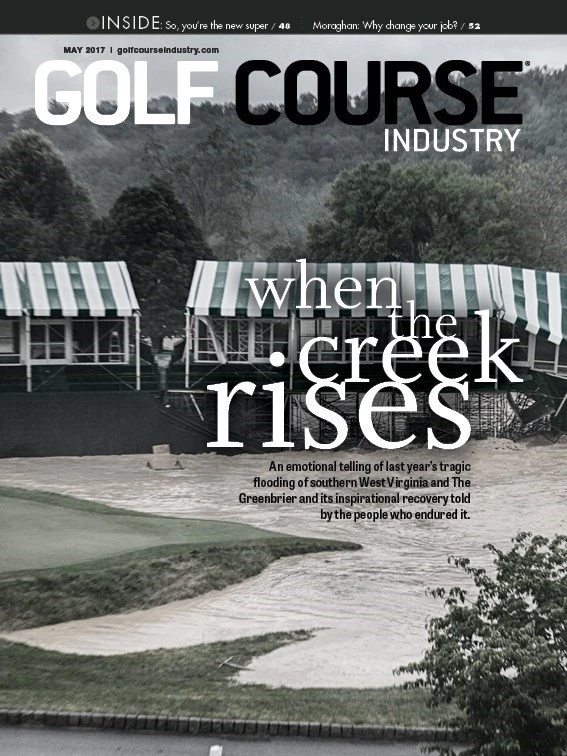

Explore the May 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- PBI-Gordon promotes Jeff Marvin

- USGA investing $1 million into Western Pennsylvania public golf

- KemperSports taps new strategy EVP

- Audubon International marks Earth Day in growth mode

- Editor’s notebook: Do your part

- Greens with Envy 66: A Southern spring road trip

- GCSAA’s Rounds 4 Research auction begins

- Quali-Pro hires new technical services manager