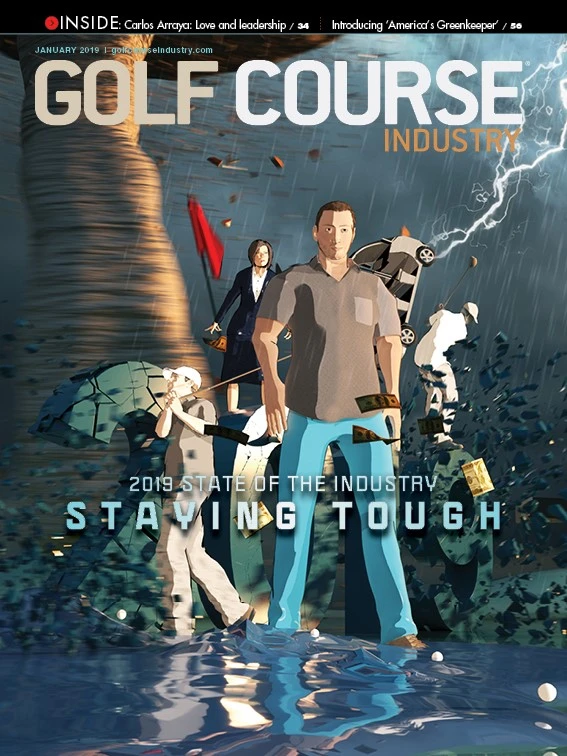

Think back a decade. It was early 2009 and we were at the beginning of the worst recession in most of our lifetimes. The golf market had already been softening since 2001 and some industry critics were predicting dire things.

One of those predictions was that we wouldn’t see much innovation – particularly new chemistry — in our business moving forward. As the recession deepened, many budget-challenged superintendents had turned to cheaper post-patent products and there didn’t seem to be much hope for brand new products to combat specific diseases and manage resistance.

But despite the recession, the innovation at BASF never stopped. Their researchers identified a promising new molecule a decade ago that, after thousands of tests and a quarter-billion-dollar investment, is now bringing new turf compounds to life.

“We have two new products in the pipeline that, if approved, will both carry on that legacy of innovation and give superintendents a couple of pretty exciting new tools,” says Kyle Miller, BASF’s longtime Senior Technical Specialist. “We’re pumped to get them approved and get them out to customers who need them.”

But let’s not get ahead of ourselves. First let’s talk about how that innovation came about and what it potentially means to you.

The skinny version is BASF is simultaneously launching several formulations of a new fungicide in both the agriculture and turf markets – something unusual because most new actives get their start on the farm before ever moving to golf. The basic active ingredient, called Revysol, has been developed in two turf formulations: Maxtima, a stand-alone version of the AI, and Navicon, a premix combination of Maxtima and Insignia. The active in Revysol and Maxtima is mefentrifluconazole, an entirely new compound that offers both disease control and significant resistance management qualities.

So let’s rewind the tape and look back at how these new tools started as an idea on a chalkboard somewhere and eventually turned into field-ready tools for turf managers. To do that, we talked with both Kyle Miller and Dr. Renee Keese, BASF’s R&D Project Leader, to get a look at the remarkable process of bringing new products to life in 2019.

Q: Describe your overall role in the process.

Keese: My role is to begin characterizing the active ingredient specifically for turf or ornamental uses. We typically have some understanding of how it could work in corn, soybeans or wheat, and now we need to focus on our pathogens, application rates and timings for a superintendent. I help figure out what the directions for use will look like and put together the data package for EPA and state registrations, if they are needed.

Miller: As products are submitted to the EPA for registration, our group gets involved to help try to answer additional questions turf managers may have about a new product with research trials focused on practical use. We are also instrumental in training our sales reps, distributor reps and end-use customers.

Q: What do end-users – particularly superintendents – need to understand about how a new product comes to life?

Keese: Sometimes it’s serendipity, sometimes it’s a lot of work for a chemist to create what we are seeking. Revysol took several years and focused research to achieve this active ingredient and formulation.

Miller: They also need to know that the process takes nearly a decade from start to finish and a lot of steps have to be completed and gain approval before continuing. It’s also very costly.

Q: Can you characterize the size of the investment in the total process in terms of time, money and focus?

Keese: Over the course of eight to 10 years, we spend an average of $286 million to develop a new active ingredient. These two new turf products fit into this scenario. This chemistry has been my focus for the past six seasons!

Miller: Right. Superintendents are often amazed to find out a new product will cost in the range of $300 million to bring to the market. That’s not only a lot of money, but a lot of resources inside our company and in the field to make it all happen.

Q: What kinds of exercises or processes do you use to identify the need for potential new products?

Keese: We do have specific gaps in our portfolio that we try to fill, and then we hear from customers and sales reps with their “wish list” ideas and input. In this case the Revysol/mefentrifluconazole was specifically created to be a different DMI – keeping efficacy and turf tolerance top of mind. BASF was trying to make a good class of chemistry even better.

Miller: We really do a little bit of everything: focus groups, informal feedback from customers and field sales people, collaboration with the ag team ... plus having an experienced T&O group that helps identify needs based on years of experience.

Q: When you think about Maxtima, what was that moment?

Keese: ?After early screens with Maxtima I knew we had a good fit for turfgrass. The efficacy on Anthracnose was a big moment for me.

Miller: One of the issues with DMIs is their limitation for use during the summer months because of phytotoxicity. As we evaluated Maxtima, even at elevated rates we saw that during the summer, it had no negative effects on the turf. This is quite unique for this class of chemistry.

We decided to take it a step further and look at combining it with a strobi.? Given the diseases Maxtima controls and its other attributes, particularly, summer safety, we knew that a premix of Insignia + Maxtima was a natural to provide the increased disease spectrum and plant health benefits.

Q: How did you gain internal consensus that these new concepts were worth looking at?

Keese: Often we need to see how it is performing in early stage testing, to then piece together where we see the fit for a superintendent. If I can show marketing colleagues that we can control some of the key pathogens, at a low use rate, while providing excellent safety, they quickly become interested.

With the Revysol chemistry, strong anthracnose and dollar spot control were key identifiers for our discussions. The ability to rotate chemistry for resistance management was also important, with so many SDHI and QoI chemistries available.

Miller: Ultimately we felt like these products could fill an unfilled need for superintendents. Excellent control of key diseases like dollar spot, anthracnose and spring dead spot with excellent summer safety.

Q: What things have to happen before you ever put a drop of experimental product on a turf plant in the lab?

Miller: Sometimes what we do is initially driven by our crop counterparts so when they give it a thumbs up, we are eager to test it. In this case we were actually involved in the early screens, at least to know it wasn’t harmful to turf, and we were included in the first wave submissions to EPA. That gets us to market quicker.

Q: What barriers have historically stopped new concepts from coming to market?

Miller: Registration problems like an adverse environmental profile or mammalian toxicity can stop a product before it starts. But we also have to look at the cost of production, limited scope of control on the disease spectrum or just being just a “me too” product. There are lots of hurdles to overcome!

Q: What was important about each of these products that made them worth developing?

Keese: for me it was the high degree of efficacy and the safety to turfgrass species all season long. We saw this early on and it was really intriguing to us. On top of that, we didn’t see any phytotoxicity issues with ultradwarf bermudagrass, even when applied in the middle of the summer. The comparisons to standard DMIs were pretty telling.

Q: Final thoughts on why these products had such good potential they were worth the investment?

Miller: With many new SDHI’s on the market and no new DMI’s being introduced in over 15 years, these products will have excellent utility as part as an overall disease control program. Fundamentally we’re running out of DMIs and this gives that class new life. We think superintendents will love that.

Explore the January 2019 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- From the publisher’s pen: Conscientious of a bigger role

- Bernhard and Company partners with Laguna Golf Phuket

- Terre Blanche showcases environmental stewardship

- VIDEO: Introducing our December issue

- Bernhard and Company introduces Soil Scout

- Nu-Pipe donates to GCSAA Foundation’s Centennial Campaign

- GCSAA enhances golf course BMP tool

- Melrose leadership programs sending 18 to 2026 GCSAA Conference and Trade Show