It’s turf show/conference season again, and the conferences and shows offer a multitude of excellent educational sessions. These sessions are usually well attended, especially on the golf side, and provide not only an opportunity to obtain Continuing Education Units (CEUs), but opportunities to learn. These educational programs often have multiple tracks for golf, sports turf and landscape. The good ones also have a mechanics track.

I have noticed a lack of maintenance during my evaluation and audits of golf courses. This is no big news because most golf course irrigation maintenance is reactive, not proactive – fix what’s broken not what’s working. Lately, however, I’ve observed a lack of irrigation knowledge by the personnel doing the actual irrigation maintenance. So, how come when we go to a golf-oriented conference and show there is very limited education on irrigation and basically none about irrigation maintenance? There may be a short irrigation talk, but nothing of substance. Many times, the irrigation subject matter is new technology or equipment related, not maintenance related.

Why is irrigation training important? True to its name, an irrigation system is a “system.” At some point, someone spent a considerable amount of time designing that “system” to make sure it operated correctly and applied water as uniformly and efficiently as possible given the equipment available at the time. Unfortunately, very small changes to an irrigation system will quickly make the system less uniform and efficient.

For example, the original design used a certain sprinkler model with a specific nozzle to operate at a set pressure. Put in the wrong nozzle, and the system is not the same. As a result, the precipitation rate changes as well as the distance of throw, how much water it uses and the uniformity.

Have you ever trained your irrigation technician or staff in making sure the nozzle replacement is the same as the nozzle that broke or blew out and is being replaced? I see many golf courses where the nozzle variation for the same sprinkler on a feature is all over the place. I recently visited a golf course where each fairway had all five available 670 nozzles in the fairway sprinklers. Along the same lines, the sprinkler needs to be set with the right pressure setting or you have the same issues as with the nozzle replacement. It is also important to replace sprinklers with the same model as they are all slightly different, although this poses a challenge with older systems.

What else do irrigation maintenance personnel need to be trained about? If your irrigation system has smaller sprinklers that are not valve-in-head, they need to know what match precipitation is and what the flow control on a valve is for. That way the block zones water evenly and the pressure is appropriate for the sprinklers installed. Does everyone working on the irrigation system know how to make a proper wire connection – extremely important on two-wire/decoder system – that is waterproof with a consistent connector used throughout the golf course? How about something as simple as a repair coupling? Are they using solvent weld cement fittings for repairs that should be done with ductile iron or gasketed repair couplings? Do they know the proper way to install a repair coupling so it doesn’t stress the pipe and so it will last? Many golf course irrigation system repairs are repairs of previous repairs – hence the repair was probably not done correctly in the first place. Of course, there is my personnel pet peeve of keeping sprinklers level and at grade. That is preventive maintenance, not repair. Train your personnel to level and set sprinklers at grade when they are not repairing other parts of the system.

What about when there is a wiring issue? Do they just twin sprinklers together or do they track out the wires and find the issue? Does your staff routinely check the system operation to see if the sprinklers pop up and down, turn, and go on and off? Do you have your staff replace broken valve box covers routinely to reduce liability? Do they ever clean out the valve boxes? Do they exercise gate valves at least annually so they do not stick open or closed and when they replace them? Do you have them use a quality valve or whatever can be found?

The difference between reactive and proactive maintenance is whether your irrigation maintenance personnel take the quickest route to fixing a problem or they try and figure out what caused the problem and execute a repair that will last.

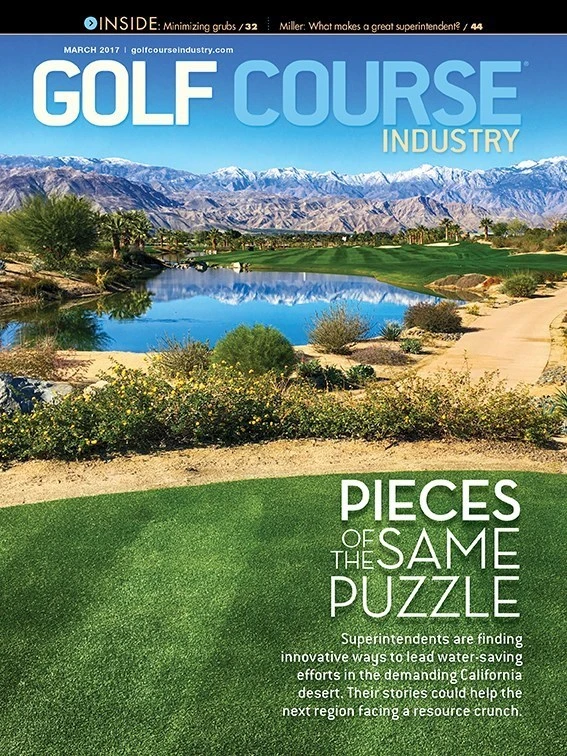

Explore the March 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- From the publisher’s pen: Conscientious of a bigger role

- Bernhard and Company partners with Laguna Golf Phuket

- Terre Blanche showcases environmental stewardship

- VIDEO: Introducing our December issue

- Bernhard and Company introduces Soil Scout

- Nu-Pipe donates to GCSAA Foundation’s Centennial Campaign

- GCSAA enhances golf course BMP tool

- Melrose leadership programs sending 18 to 2026 GCSAA Conference and Trade Show