It may not seem like it from the outside, but the typical golf course irrigation system is rapidly changing. It’s no surprise these changes are being driven by technology. Now some may think that change is not a good idea, but others love state of the art – even if it doesn’t quite work right out of the box. Because it is technology, you would think these changes are most prevalent on the control side and that is true, but the technical advances available on the control side have also spilled over into sprinklers and pump stations.

On the control side, we have the now age-old battle of 2-wire vs. satellites. Although satellites are winning a few battles, 2-wire is winning the war, which is not surprising considering most research and development efforts are on the 2-wire side. Manufacturers always continue to improve software, but they’re pretty much the same for either type control system. The future looks like 2-wire and for good reason. Conventional satellite systems send signals down a single wire; 2-wire basically sends data down a two-wire cable. A data wire can handle more information, more sophisticated signals and anything it is attached to can provide information. There’s also more feedback because the cable can interact with everything on it.

2-wire systems are good at troubleshooting themselves. If you have an electrical issue, they can pretty much take you to a few feet from the specific place where the problem is occurring. They can also do trending and provide baseline values so you can tell when equipment may be deteriorating or about to fail. This is done on some systems by looking at the voltage and amperage at the individual sprinkler. This is all great, but the most intriguing thing about 2-wire is what it may/will be able to do in the future. Which takes us to the sprinkler.

Because the control system has gotten more technical, the sprinkler has gotten smarter to deal with it. What you’re seeing on the 2-wire side is a larger case to house additional equipment, a smart module or both. The equipment/module varies in their approach, but each allows the manufacturer to provide more information at the sprinkler or to obtain more data that can show up on the central control system software. Again, what might this allow in the future: pressure readings, arc adjustment or flow at the individual sprinkler?

With irrigation and pump system controls, we are seeing various apps that are available to program, troubleshoot, and monitor irrigation and pump systems accessible through any number of smart devices. On pump systems using the app is like standing in front of the control panel and you can pretty much do anything on the app that you can do at the control panel. Remember that the app does not see or hear, so it is still a good idea to visit your pump house every once in a while to make sure there are no odd noises or spraying water.

Pump stations have also changed due to technology. Most of this is seen in better and smaller components, but also includes flow meters, user interfaces and interacting with the irrigation system controls. Sensing and monitoring options are also more readily available.

Today’s pump station uses magnetic flow meters as standard as opposed to paddle wheel. Filtration controls are integrated into the pump control panel as opposed to stand alone. User interfaces are touch screens or full-blown computers as opposed to switches and key pads. Monitoring of power use, electrical conductivity (salt) and turbidity are also available. The irrigation/golf industry is also close to having most pump stations being able to interface with the three major manufacturers of golf irrigation equipment although not all to the same degree. This interaction allows the irrigation system schedule to react to actual pump station flows and pressures and to have the pump system operate as efficiently as possible.

There is the ongoing HDPE vs. PVC debate, and there is change occurring there as better fittings and valves become available for both, but especially HDPE. All PVC systems are becoming rare, but there are many hybrid systems being installed with PVC mainlines and HDPE laterals as well as all HDPE.

The lag in irrigation system sales from 2008-16 didn’t curtail product development. But with the current surge in golf course irrigation systems, things will continue to change as even more dollars are invested in upgrades and new products. This will benefit the end user who takes the time to invest in change and learn the new technologies in terms of lower water use, less repair labor and ultimately better turf conditions.

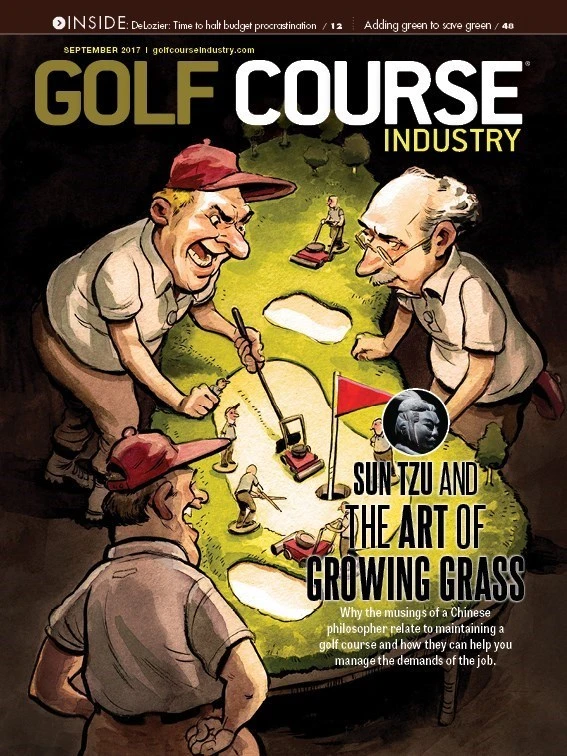

Explore the September 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- LOKSAND opens North American office

- Standard Golf announces new product lineup for 2025

- The Salt Pond taps Troon for management

- KemperSports selected to manage Swansea Country Club

- From the publisher’s pen: Grab that guide

- Introducing our April 2025 issue

- South Carolina leaders honor golf course superintendent

- One and only