I visit lots of golf courses and see a lot of irrigations systems. They vary in terms of their customer base from public, to resort, to country clubs, to high-end private courses. One thing they all have in common, though, is an irrigation system the superintendent does not think is as good as it could or should be. Many times, I am asked to evaluate the condition of an existing irrigation system. The thing I like about golf course irrigation system evaluations is after you see what the system’s problems are, you get to figure out the cause. With golf course systems, the problems can stem from many different factors, including pump station issues, pipe size, sprinkler nuzzling, sprinkler spacing, pressure, controls and wiring issues. The trick is to determine the issue’s primary cause or whether it’s a combination of factors.

One aspect of evaluating an irrigation system is to check the operating pressures to see if the sprinklers operate at the pressure the designer intended and the pressure that meets the sprinkler manufacturer’s requirements. In golf, higher pressures are usually regulated to the desired operating pressure based on the sprinkler pressure regulators setting if it is receiving 10 to 15 psi above the required setting. However, low pressures severely distort the sprinklers pattern resulting in poor uniformity and wasting water. You don’t need a professional to check pressures. Your staff can do this task with just two pressure gauges.

Put one gauge at the highest point of your golf course and the other at the lowest. Attach the gauges to the hose connection of a quick coupler key and insert the keys into the appropriate quick coupler/snap valve. Put one person on each gauge and someone in the pump house. The person in the pump house will log the pressure at the pump house, as well as the flow and what pumps are operating. Even though the purpose of the test is to evaluate the sprinkler operating pressures and piping system, a side benefit of pressure testing is it also shows how well the pump system operates, maximum available flow, how well the pumps switch, etc.

Once everyone is in place, slowly turn on a number of sprinklers at a time. The number to turn on at a time will vary with your pump station flow capacity. You don’t want the test to take forever. A good rule of thumb is 0 to 1,000 gpm, two sprinklers at a time; 1,001 to 2,500 gpm, four sprinklers at a time; and more than 2,500 gpm, eight sprinklers at a time.

At each step, record the pressure at the three locations and the flow, as well as what pumps are operating. Spread the water out throughout the course as you would your central control system. On a small pump station, you may want to do two tests – even holes and then odd holes.

Keep turning on a set of sprinklers until you run the pressure at the high point well under the desired sprinkler operating pressure or the capacity of the pump station. On a system with an 80-psi operating pressure, turn sprinklers on so the pressure at the high point is down to at least 60 psi or less. Keep all the sprinklers on for about an hour so nothing turns off during the test. The results will give you the maximum flow the station can produce at the intended operating pressure and how many sprinklers that represents. Expect to see significant differences between the high and low points. You will see the pressures change significantly at each step as you get closer to the pump station capacity and turn on sprinklers on the holes where the gauges are located. You may see the flow change as each set is turned on and get smaller as you reach the pump station capacity.

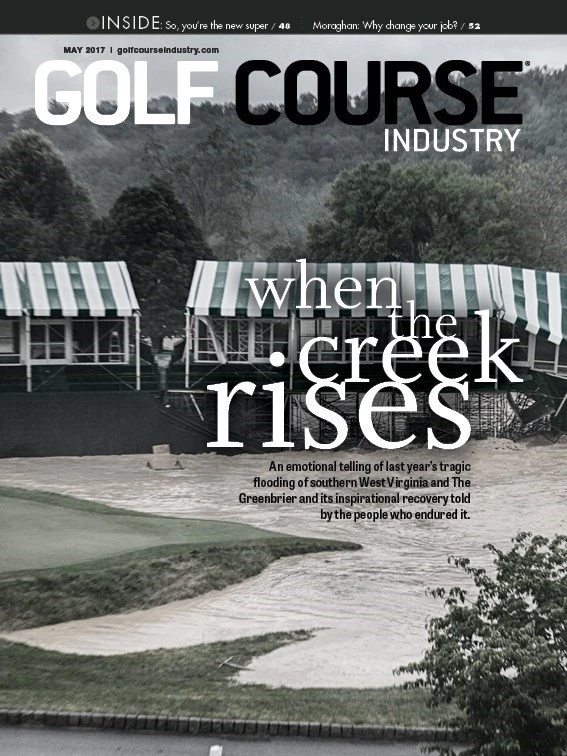

Explore the May 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- From the publisher’s pen: Conscientious of a bigger role

- Bernhard and Company partners with Laguna Golf Phuket

- Terre Blanche showcases environmental stewardship

- VIDEO: Introducing our December issue

- Bernhard and Company introduces Soil Scout

- Nu-Pipe donates to GCSAA Foundation’s Centennial Campaign

- GCSAA enhances golf course BMP tool

- Melrose leadership programs sending 18 to 2026 GCSAA Conference and Trade Show