We’re all aware a new irrigation system is expensive, and costs are escalating quickly. The competitive market has kept the hard goods (sprinklers, controllers, swing joints, etc.) from skyrocketing, but the costs of accessory items (pipe, fittings, wire, valve boxes, isolation valves, etc.) continue to climb.

These expenses are minor compared to the installation costs. Due to a large increase in demand for golf course irrigation systems, there are fewer qualified contractors available. The result is an increase in qualified golf course irrigation contractors’ labor costs and a decrease in their availability. The 2017 and beyond irrigation market is much better than we have seen over the last 10 years or so. Unfortunately, you will pay for it. So, if your course needs a new irrigation system, how can you save on costs? And, what are the pros and cons of not doing a complete system replacement to save costs?

Not replacing the mainline pipe is the most significant cost saving item. Maintaining your mainline pipe will also save money on fittings and possibly the mainline isolation valves, drains and air release valves. We know PVC pipe has a life expectancy that exceeds 50 years, and while we are not sure yet on HDPE, it also has a long life. Most mainline pipe systems are not replaced due to age, but because they are transite (asbestos cement), too small to support an expanded irrigation system or the fittings are failing. Depending on your existing mainline fitting type, the fittings will lifecycle out, especially if they are gasketed PVC or epoxy-coated steel. Saddles tend to move with time or the seals fail. Ductile iron fittings have a long life also exceeding 50 years. But if your mainline fittings are failing or about to lifecycle out, you will need to replace the mainline because replacing fittings is not economically viable even if you know where they are located on the golf course.

Isolation valves are the other issue with mainlines. Over time isolation valves either stop closing/opening or do not close tightly, and some might even break the stem which opens and closes the valve. The good news is they are replaceable in the field. And while not an inexpensive task, they can be replaced over time as budgets allow.

Small gate valves wear out even faster than mainline isolation, and their condition is based on their initial cost. If they were cheap, foreign-made valves, then they will have more issues than more expensive valves and will need to be replaced if new laterals are being installed.

When considering whether to replace the mainline, you need to consider the water window. If you are substantially increasing the number of sprinklers or the irrigated area, your overall watering time will increase. If you are already taking six-plus hours to irrigate, then the water window will be longer. I recently dealt with a course that wanted to save $1 million by not installing a new mainline. However, due to the existing mainline’s size and the increased number of sprinklers for the new system, the water window was potentially changing from eight hours to 14 hours.

The irrigation control system is another place for potential savings. If your existing controllers are functional and you do not visit them often, then why replace them? You could keep those controllers as part of a new system and just add additional controllers as needed. The downside is the inability to switch control system manufacturer or technologies. And you may be prohibited from gaining all of the benefits of today’s irrigation control system hardware because the existing controllers may be limited due to the manufacturer.

There are other savings to consider such as excluding weather and lightning protection systems, but they will not have the significant impact of a mainline or a control system. You can save small amounts with components such as PVC swing joints as opposed to brass for quick couplers, less isolation, and the type of fittings for both laterals and mainlines (saddles versus service tees). Not having individual sprinkler control would save some money, but is not usually a good idea. You can reduce the amount of grounding as well, but you must weigh the cost of grounding against the risk of damage to the electrical components.

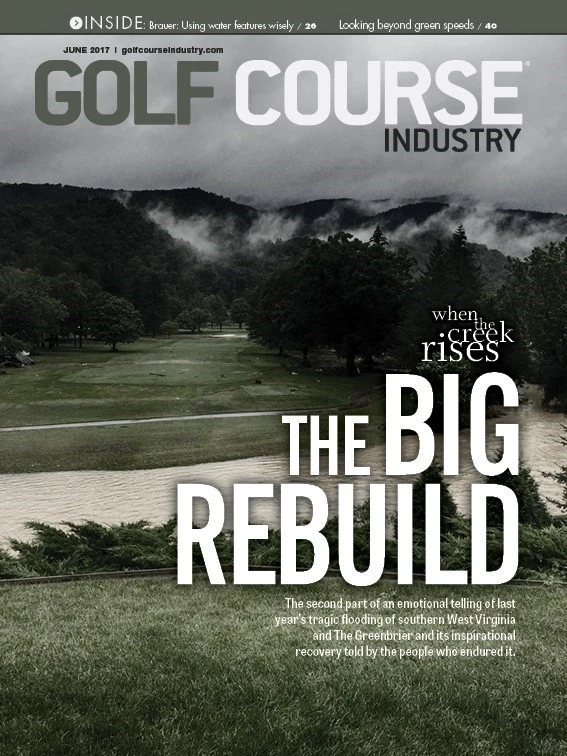

Explore the June 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- From the publisher’s pen: Conscientious of a bigger role

- Bernhard and Company partners with Laguna Golf Phuket

- Terre Blanche showcases environmental stewardship

- VIDEO: Introducing our December issue

- Bernhard and Company introduces Soil Scout

- Nu-Pipe donates to GCSAA Foundation’s Centennial Campaign

- GCSAA enhances golf course BMP tool

- Melrose leadership programs sending 18 to 2026 GCSAA Conference and Trade Show