| It’s hard to beat the heat out at the Rio Verde Country Club right now. Recovering from a very cold winter with several days of frozen soil, the 210-acre, 36-hole course is missing many of its members, who mainly come in during the cooler months. “Many of the members are snowbirds, which means we have about 30 percent of our membership at the club during the warm season when it’s hot. And it’s been hot lately,” says Don Pleger, superintendent. “We hit about 116 last week. It’s just been really hot with little rain. We get somewhere between seven and eight inches of rain a year, mostly in January and August, with the rest scattered through the year.” And if the weather doesn’t make it tough enough to grow the fairway 328 and 419 or the TifDwarf Bermudagrass, he has to contend with soil that doesn’t make him feel too welcome. “We’re at 1,593 feet above sea level. We’re on the side of a mountain, so we don’t have the best of soils. A lot of it is crushed granite,” says Pleger. “We’ve got the fairways tilled up and added some sand to keep it loose. It’s not bad but if we don’t keep at it, it’s always ready to go back to solid rock.” The soil doesn’t hang on to water well, but even if it did, the quality of the water isn’t going to help, either. It checks in at about 8.5 to 9 pH, with high levels of bicarbonates and salt. During the winter, Pleger makes up about 40 percent of his water budget with reclaimed water, but in the heat of the season, he has to work with the pH-heavy well water, and he has to use a lot of it. “This time of year, we’re using 600,000-700,000 gallons on each course each night. When it’s 110 and you don’t put it on heavy each night, you’re not going to make it to the next night,” he says. And there’s good reason to keep those greens strong. They’re growing in to USGA standards after bringing them up a few years ago. As the economy slowed down, the members of the private facility dwindled. It was decided that now was the time to try to bring in some new members with a redesign of the course. “It was decided that it was a better idea to spend money more on the appearance and design of the course to try to attract new members,” says Pleger. “We’ve gone down from 800 members to 465. So we would change the design and live with the irrigation system we’ve got now.” Working with his current irrigation system didn’t really hold Pleger back, since the one thing the soil didn’t do was wear down his pipe system. “Because our ground doesn’t tend to freeze as much out here, an irrigation system can last 20-30 years,” he says. “It’s the sprinkler heads that need updated as we go. We started changing them out about 2006. The renovation cost $6.5 million. We didn’t have the money to afford upgrading the total system or the entire course, so we’re updating it in pieces. Three or four years ago, we redid the greens to USGA standards. The fairways are in good shape. We got a new pump station in 2010.” As the water wore down the sprinkler heads on his course, he planned to make a move – but it had to be a cheap move, given his budget was still growing in from the prior renovation. “It was because of money. It took everything this club had to do the renovation project,” says Pleger. “We started working on each head. We deal with Toro and have Toro equipment, and along with the equipment, Toro just kept giving us good numbers. We get good service with them and have a good relationship with them. They’ve been a big help with this project.” In 1996, he ran with the 700 series Toro sprinkler heads. Now, he’s upgrading to the new 835S and 855S series, which fit the internal body. The aging sprinkler system, with 3,531 heads throughout the two courses and driving range, could be changed more cheaply than a full replacement. The course has replaced heads throughout the last few years a few at a time, making the transition easier even in a tough economy. But he didn’t have to wait long to start seeing improvements around the course just from the new sprinkler heads. The first things to go were the rings of uneven distribution around the old heads. “The newer heads have a better distribution pattern,” he says. “We think we’re getting better distribution from them. We seem to have eliminated most of the donuts with these.” The newer model also gave them better control over where the water was meant to go, a big perk for courses in close quarters with new development. “They have a few more options with the nozzles, which is nice because houses line the course,” he says. “Everything’s set at 65 feet, but some of the houses are closer, so we can change it. It’s got more of a standard nozzle and it’s easy to change. “You can adjust the arc on them as well, from 17 to 23 degrees, which helps us because we’re able to aim low to get under the trees on the course.” But the best new advantage for the changing course was simply being able to come full circle with the replacement heads. “We’re able to adjust the range from part to full. That saves us because we can use fewer sprinklers throughout the course and just adjust them as we need to,” says Pleger. “If it’s on the fairway it can go 360, and if it’s on the edge of the fairway it can go 180 or 270. Now it’s the same in any spot. “It was just versatility of those heads, where we used to have to buy full and part sprinklers, we could just get one and have just one kind on the cart and can use them in either place. By using newer heads, we’re getting a better standard all around. Everyone seems to be happier with it.” And keeping things simple avoids one of the biggest problems for superintendents trying to save money by changing out heads, he says. “The biggest mistake I’ve seen superintendents make is to keep experimenting with these products,” says Pleger. “I don’t have to have more than one kind of sprinkler out there. If they’re going to change, they should pick a product and stick with it. It’s simplified our inventory and repair jobs.” Pleger, however, isn’t likely to bring another sprinkler in to this system for a while. “We’re really happy with the 835s,” he says. “They’re an easy sprinkler.” |

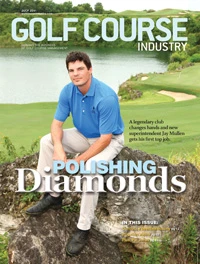

Explore the July 2011 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- Advanced Turf Solutions and The Aquatrols Company release soil surfactant

- Heritage Golf Group acquires North Carolina courses

- Editor’s notebook: Green Start Academy 2024

- USGA focuses on inclusion, sustainability in 2024

- Greens with Envy 65: Carolina on our mind

- Five Iron Golf expands into Minnesota

- Global sports group 54 invests in Turfgrass

- Hawaii's Mauna Kea Golf Course announces reopening