In recent years, technology has born new types of control systems. As with any new technology, they have scared some, excited others and confused even more. Sorting through the irrigation control systems available on the golf market can be a daunting task. Golf course irrigation control systems are expensive, and depending on the bells and whistles you include, the price can vary dramatically. Let’s take a quick look at the various control systems available today.

The basic system is a manual system and, believe it or not, they’re still out there. But let’s move on to a basic automatic system which would consist of standalone field controllers. These systems provide a large step in automation, but the operator usually has a spreadsheet that they’ve developed over time to make sure the start times don’t overlap too much and exceed the water supply capacity. These supers dream of having a central control system that manages the field controllers and allows them to toss the spreadsheet. Of course in today’s market we have field controller systems and decoder/two-wire systems. When talking about standalone systems without a central we are usually talking about field controllers, but some manufactures do make decoder systems that operate from field controllers without a central.

Next, we have the typical golf course irrigation system consisting of field controllers or decoders/two-wire system operated by a computerized central control system, which may include a handheld remote control for field operation and a weather station for providing relative ET values. It may include soil moisture sensors, pump station communication and operational access through a smart phone. These days the options are limitless.

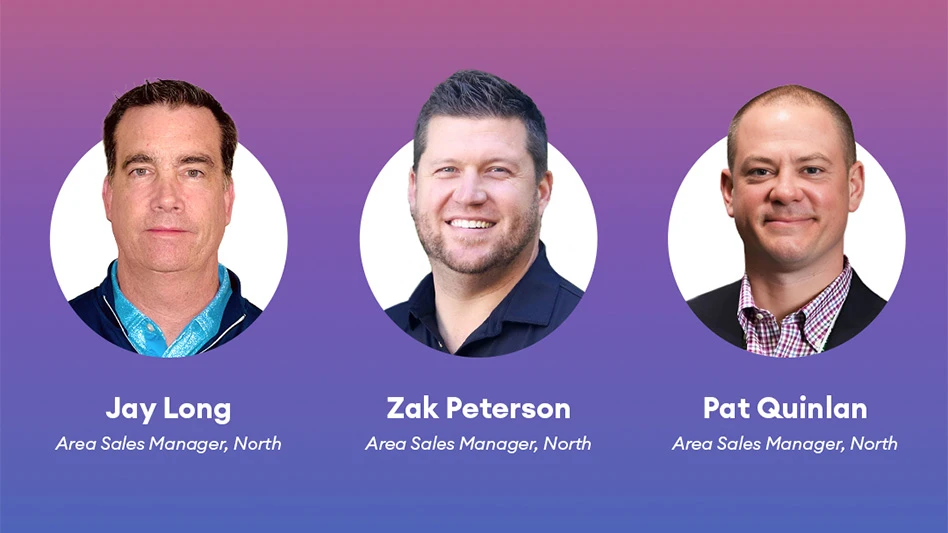

Since this all seems pretty straightforward, where does all the decision-making occur? The computerized central control system is the basic and most important component, but what equipment do you choose from to help the computer out? There are conventional field controller systems and decoder/two-wire systems. You need to decide what type of control system is best for your golf course as well as determine what control system best fits your management style and allows you to sleep at night. Your local sales representative can review the various pros and cons of their basic control equipment versus the competition and why theirs is better. They will also have an opinion on what system you should purchase.

Certainly with the decoder/two-wire system there is less wire than with a field controller system. Field controller systems also have the cost of the controllers in the field, but these costs are offset by the cost of the decoders themselves or the more expensive costs of the sprinklers. Where the water gets muddy is in the lightning protection – grounding and surge suppression – that is required for the field controller system versus decoder/two-wire systems. A typical field controller system may have somewhere between 20 and 30 controllers for 18 holes. Some are more and some are less, but the controllers would be grounded per location or, depending on your designer, may be grounded per controller. The grounding will include at least a rod, three rods or a combination of a rod and a plate depending on the design.

Additionally, a good system will have a #6 bare copper wire throughout the system to act as a shield/bonding wire. Grounding connectors would be exothermic (Cadweld type) which is a better connection as opposed to a clamp type. The system might also have a lightning detection system that disconnects both field controller power and communication when lightning is detected. Grounding for field controller systems has been adapted over time and follows for the most part American Society of Irrigation Consultants standards. There is not a lot of variation in what is designed and installed.

On the decoder/two-wire systems the grounding requirements are manufacturer driven. A typical decoder/two wire design might be a grounding “system” every 500 feet or every 15 decoders/solenoids and at dead ends or something similar.

So the question becomes: Is this enough and what does the grounding consist of?

To be continued! GCI

Explore the February 2011 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- From the publisher’s pen: Technology diffusion and turf

- Applications open for 2025 Syngenta Business Institute

- Smart Greens Episode 1: Welcome to the digital agronomy era

- PBI-Gordon promotes Jeff Marvin

- USGA investing $1 million into Western Pennsylvania public golf

- KemperSports taps new strategy EVP

- Audubon International marks Earth Day in growth mode

- Editor’s notebook: Do your part