Gate Valve Key Holder

Gate Valve Key Holder

The 2-by-2-inch square-nut irrigation gate valve key used to bounce around in the back of the 2007 John Deere Turf TX Gator 2WD. The roof was removed and the two factory-mounted brackets that held the roof in place on the front hood were modified by adding a U-shaped bracket with holes drilled on either side for a lynch pin to hold it in place. The gate valve key is held firmly in place and it fits perfectly tight. The bracket was made from recycled parts from an old farm harrow/seeder. It took about one hour of labor to modify both brackets. Timothy Brown Cope, superintendent at the Penny Branch Club in Furman, S.C., conceived, designed and built this great idea.

Homemade roller

Homemade roller

This homemade roller is used to roll the Bermudagrass greens after aerification so that they are smooth and that no scalping occurs when they are subsequently mowed. The roller was made using mostly recycled parts from discarded equipment. The red-colored 1994 Lely Model 1250 3 point hitch frame was used after the hopper, spin paddles and gear box was removed. The front-end frame from an old Massey Ferguson tractor was used for the horizontal framework. Two-and-half-by-2 ½-inch square tubing was welded horizontally to the tractor frame and ¼ inch thick steel plates were welded vertically to the square tubing to mount the roller. Homemade bearing brackets were made to mount the 1990s vintage Verti Drain Fairway Aerifier 6-inch diameter heavy steel roller. Portable tractor weights are added as needed for additional weights. The ratchet strap holds another type tractor weight in place horizontally, as they also can be added as required. The Snapper lawn mower seat was added as a joke because the 18 family owners of the golf course kidded the superintendent that they could sit on the back for extra weight. The roller is mounted to a Massey Ferguson Model 1250 Tractor. It can also be mounted on a Cushman Turf Truckster with a hydraulic dump bed, where the hydraulic cylinder is used where the turnbuckle would normally go and extra pins were added to the roller frame to hookup to the dump bed pin locations. It cost about $100 for the bearings and homemade bearing brackets and it took about two afternoons to build. Timothy Brown Cope, superintendent at the Penny Branch Club in Furman, S.C., conceived, designed and built this unique idea.

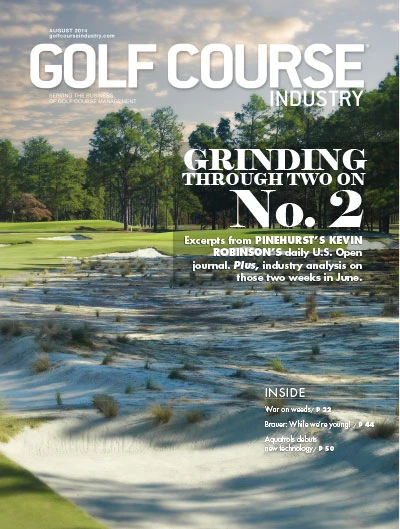

Explore the August 2014 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- Editor’s notebook: Green Start Academy 2024

- USGA focuses on inclusion, sustainability in 2024

- Greens with Envy 65: Carolina on our mind

- Five Iron Golf expands into Minnesota

- Global sports group 54 invests in Turfgrass

- Hawaii's Mauna Kea Golf Course announces reopening

- Georgia GCSA honors superintendent of the year

- Reel Turf Techs: Alex Tessman