EDITOR'S NOTE: There was an attribution error in the print version of this article. Content and quotes contributed by Colleen Tocci, marketing manager at Engage Agro USA, were incorrectly attributed to Colleen Clifford, marketing manager at Aquatrols. In addition, images used in the story did not receive the correct attribution for Engage Agro USA. GCI regrets the error. Below is the corrected version of the story.

---

There was a time when wetting agents, or surfactants, were considered snake oil. Something you might buy from a street corner huckster who would claim that they were the miracle cure for diseased turf. Rodney Tocco admits as much. The researcher at Michigan State University’s Plant and Soil Sciences Department, says this reputation was still alive and well in 2003 unless your course was located in an arid region and you had seen firsthand the benefits from salinity flushes.

“Why did people need them when they had plenty of water to use?” he says. “But now, restrictions are coming out of the Great Lakes region and Ontario, requiring the need to monitor water usage. Also, a river got run dry in Connecticut – all of which was not caused by the golf industry. But they’re now looking at these water reserves going down because of too much pressure from growing populations. So it has been an eye opener that we can put surfactants in there and reduce water input.”

Colleen M. Tocci, marketing manager at Engage Agro USA, adds that wetting agents aren’t just for water conservation, and more and more courses are seeing the multiple other benefits they offer.

“With the formulations we have today, there are so many other benefits beyond water savings,” she says. “You get into chemical efficiency, irrigation efficiency and playability because you’re creating healthier turf and roots and those help fight off disease and insect pressure. You’re just creating a healthier environment in the soil profile.”

Still, Tocci admits that one of the most common reasons to use injectable surfactants is to increase the efficiency of your irrigation system.

“A lot of money has been spent over years upgrading and improving overall irrigation systems on golf courses,” says Tocci. “However, you can modify your irrigation system as much as you want, but if the water you’re applying through that system and whatever other chemical you’re applying through that system doesn’t get down to the rootzone, it doesn’t much matter that you’ve spent all this money on upgrades.”

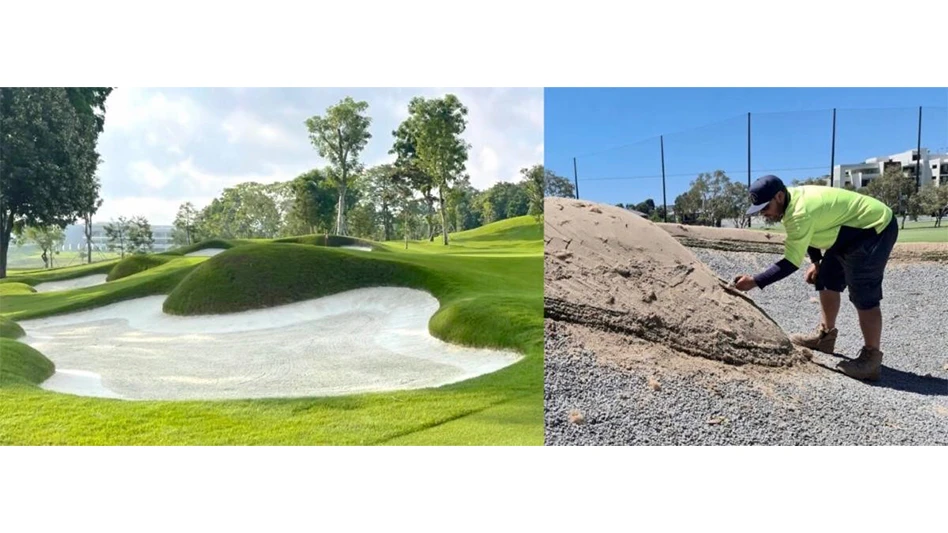

On a greens or tees program, Tocci says, you’re typically looking to alleviate water repellency issues in USGA sand profiles managing hot spots or localized dry spots that can pop up on the course.

Water repellency, you say? Yes. This is probably the perfect place to explain how wetting agents work. According to Tocci, soil particles can become hydrophobic or water repellent after years of typical cultural practices (ie. Breakdown of fertilizer and buildup of some topdressing products) and natural processes such as decaying plant roots, certain fungal species, surface waxes from plant leaves, and decomposing soil organic material that create a water repellent, organic coating on the particles.

“Surfactants help create sites on those particles making them water receptive or hydrophilic,” she says. “Surfactant molecules help the soil particles accept the water and allow hydration.”

Turning soil into a “water lover” versus a “water hater” is something MSU and Winfield’s Rodney Tocco has seen firsthand. He conducted a study with wetting agents over a three-year period, where the first year was mild, the second year was wet and the third year was the hottest, driest season in Michigan in 100 years. And that’s when surfactants really wowed.

“They really stood out for what I was doing in the environment to help sustain turfgrass, particularly on putting greens,” he says. “We received no rain for two months, and wetting agents kept things alive.”

Tocco believes wetting agents have really ramped up in popularity especially over the last couple years with the lack of moisture and rainfall.

“One of the things surfactants do is help modify the environment so we get the benefit from those peaks we see and keeping them more moderated.”

It’s important to note, however, that all surfactants are not the same. There are multiple classifications, and new ones are constantly being introduced to the market. Ones you would use on your greens would not be ones you would use on your fairways because you’re dealing with different soil types and different cultural practices. That’s where you get into different formulations and classifications of chemistries.

“If you’re looking for something that will help water to penetrate, there are products just for that,” says Engage Agro USA's Tocci. “Then there are products that will help water to penetrate but will also have a residual in the soil profile and help facilitate continued hydration.”

Tocci says there are also products that go beyond that and are long-term and don’t break down as quickly in the soil, holding on longer and helping hydration and rehydration in wet/dry cycles. “Some people want a long term product so they don’t have to apply as frequently, but others are just put through your fertigation system, which makes it a no-brainer if you’re treating your fa

irways because you don’t have to monitor the application closely.”

Wetting agents have been around since the 1950s, but Tocci says today’s formulations are definitely better. With block copolymers, triblock copolymers and multi-block copolymers, modern wetting agents have three different components that can battle the different soil particles and what is causing water repellency.

Some wetting agents are meant to be used preventatively to prepare the soil for what’s coming, but others, both liquid and pellet formulations, can be used for spot treatments, including a pellet by Engage. This pellet is comprised of 10 percent seaweed, which provides some beneficial kickbacks to the turf. They can also be used as tank additives.

“If your soil is receptive to water, it will also be receptive to whatever chemicals you apply,” Tocci says. “Most surfactants can be applied with fertilizer with no problem. However, there are a lot of requirements, especially in California, where they won’t allow you to mix it with another chemical. Many foliar adjuvants are labeled for tank mixing but soil surfactants really focus on the soil. However, if your soil is receptive to water, and two days later you go out with either a fungicide or herbicide application, you’re adding benefits to those chemicals because you have gotten your soil particles ready to accept them, more so than when they were repellent. It definitely helps aid your other cultural practices.”

Wetting agents can do a lot of things, but one thing Tocci says they can’t do, at least alone, is alleviate soil compaction.

“I’ve been in the industry for 20-plus years and I can say that soil compaction will not be alleviated solely by a soil surfactant. Compaction gets into more of a physical issue, so you’ll need to verticut, core aerate and perform other practices in conjunction with surfactants. Once those other things are done, then surfactants can help aid the movement of the water and chemicals through the soil.”

“With the ones I’ve worked with, I saw no negative to microbes, no increase in them,” Tocco says. “This was a huge thing I saw as a positive, especially in the European market where they’re locking down their pesticide storage facilities or taking them totally offline. So they’re using surfactants, which are safe and not designated as pesticides. They give you an opportunity to optimize the turf from a health standpoint, giving it the ability to combat diseases and insect pressure.”

Tocco believes another reason for wetting agents’ surge in popularity is that people are starting to see an economic return on them. Now that a greater premium has been placed on water resources, the tables are turning a little. There’s no longer just an environmental reason to use them, but monetary as well.

“People are now seeing there can be an economic value to using them,” Tocco says. “People weren’t looking at wetting agents a while ago because there was no economic impact. In fact, there probably would have been an upcharge. You would have been spending more to use a wetting agent than you would have needed. Now, economics is playing a big role. It’s good to be a good environmental steward because you’re using less water, but the economics needed to catch up.”

In a nutshell, wetting agents help level the playing field between courses that have too little water and courses that have plenty of water.

“But they also help move water through profiles that have been plugged up," Winfield's Tocco says. "With research and a gain in popularity due to economics, we’ve seen them getting used in more places we ever thought of. I know of some courses using them from tee to green, and smaller ones that are trying them out or don’t have the budget for them still because they’re still expensive for the ‘Cadillac’ products. Even areas in Michigan that have been known to have plenty of water and have never considered a water shortage are using them.”

Colleen Clifford, marketing manager at Aquatrols, also makes the important point that wetting agents are not meant to be a “cure-all,” but one tool in the toolbox for superintendents to combat turf issues.

“There is a lot of documentation on their ability to reduce your volume of water and irrigation frequency. As long as you can irrigate, they’re helping.”

But Clifford is careful to dispel the notion that, if it’s not dry and you don’t have water conservation issues and have gotten copious amounts of water and reservoirs are overflowing, you don’t need surfactants.

“Formulations today allow for increased drainage and movement of water, so surfactants will also benefit you if you have too much water or rain. It’s still a good thing to be on a surfactant program because you can help move moisture through, make greens drier and firmer, and improve playability. It’s not just a question of water savings.”

Jason Stahl is a Cleveland-based writer and frequent GCI contributor.

Looking for more information about how to employ surfactants at your course? Drainage is paramount for golf courses that see a lot of precipitation, and soil surfactants can keep help keep that water moving. Check out this podcast with Kevin Collins, territory manager for Aquatrols. Enter bit.ly/1gHFsp2 into your browser to access and listen.

WANT MORE?

Enter your email to receive our newsletters.

Explore the April 2014 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- Bloom Golf Partners adds HR expert

- Seeking sustainability in Vietnam

- Kerns featured in Envu root diseases webinar

- Toro continues support of National Mayor’s Challenge for Water Conservation

- A different kind of long distance

- Golf Construction Conversations: Stephen Hope

- EnP welcomes new sales manager

- DLF opening centers in Oregon, Ontario