To overhaul or not to overhaul? That is the question many superintendents have asked themselves about their failing irrigation systems. Are they throwing good money after bad or will minor repairs correct issues and save money?

For Eric Richardson, superintendent at Essex County Club in Manchester, Mass., the decision was a no-brainer: a new system was needed.

Entering his sixth season at Essex County Club, Richardson inherited a traditional single-row irrigation system with impact heads. It was the first automated system the club had ever installed.

Entering his sixth season at Essex County Club, Richardson inherited a traditional single-row irrigation system with impact heads. It was the first automated system the club had ever installed.

“There may not have been an issue that the old system did not have, from faulty grounding, to a lack of pressure, poor pipe sizing, faulty pumps, faulty fittings (mostly galvanized), stuck heads, lack of coverage, etc.,” he says. “The club was spending $20,000 annually just to keep the system semi-operational.

“There were no improvements that could have made the system adequate,” he adds. “It desperately needed a complete overhaul.”

A triple-row system – with part circles on the perimeter and full circle heads down the middle – now graces the fairways. The part circles are used to water some of, but not all, the mowed rough, providing a sporadic pattern allowing the farther edges to fade out into the tall rough.

According to Richardson, the design gets really interesting around the greens. There is a total of seven acres of collar-height turf around the greens, with expansions to come. To meet the different watering needs, the system was designed with four watering segments around the greens – greens surfaces, collars, perimeter roughs and bunkers. Each green surface zone has around five valve in-head sprinklers (Toro 835S and 855S) while the other segments consist of multiple Hunter I-42s, Toro 590Gs and Toro 835Ss.

“This allowed us to effectively control every drop of water applied to the golf course and saved a large number of man hours by significantly decreasing the amount of hand watering we do on collars,” he says.

The irrigation system at Overbrook Golf Club in Villanova, Pa., was not considered old (16 years), but was outdated and beginning to break down, according to superintendent Tom Gosselin.

The irrigation system at Overbrook Golf Club in Villanova, Pa., was not considered old (16 years), but was outdated and beginning to break down, according to superintendent Tom Gosselin.

“The real reasons for the replacement are the changes in the philosophy of water usage and the technical advances in the systems themselves,” Gosselin says. “Our old system was standard for when it was installed and it had adequate coverage. The glaring fault was that it was not very ‘green’ when it came to water usage.”

Water usage is a major concern because Overbrook purchases a large portion of its water. Also, they were unable take advantage of many technical advances, being limited by the physical system in the ground.

To address its issues, Overbrook installed a Toro system equipped with Lynx software. The new system is five rows through the fairways, ins and outs on the greens and has very good coverage in the rough.

“We adapted to the philosophy of more heads, less water,” Gosselin says. “This system gives us the capability to target-water our specific needs without wasting water. It also allows us to give more consistent playing conditions to our members.”

From a technical standpoint, the software breaks down a complex system to a simple and easy format so Gosselin’s team can take advantage of its capabilities, he adds.

Brian Vinchesi, president of Irrigation Consulting, has seen control and sprinkler technology greatly expand in the last five years, alone. With options such as soil moisture sensors and pump station monitors, these innovations have made systems more interactive. There are programs on the Internet that allow superintendents to monitor irrigation and pump stations, which can be controlled from a smartphone or iPad.

As for improvements on the horizon...

“There are always improvements,” Vinchesi says. “But with sprinklers, I’m not sure how much better they can get. They’ve gotten so good. When you think you’ve seen it all, something else comes out.”

When discussing irrigation issues with superintendents, Vinchesi weighs the options between a total overhaul of the system versus specific improvements. Replacing worn fittings is expensive, so it may be cheaper to replace the entire system. Swapping out the controller, upgrading the pump station or replacing sprinklers are other possibilities.

“You can certainly look at improvements, but you’ve got to look at the long and short terms,” he says. “Why spend a lot of money now if you’re going to replace the system in five years?”

Kevin Redfern, director of grounds at the Governor’s Club in Chapel Hill, N.C., brought in Vinchesi to take a look at the current irrigation system and to work with him on what’s needed in the future.

The main lines at the Governors Club are 20 years old and the epoxy-coated fittings have been depositing rust and debris, which leads to clogged heads. All the sprinkler heads were replaced in 2005, but something else is needed.

“At this point a total renovation would be the best,” he says. “However, with the economy we have, large improvements are more visible for the near future. Infrastructure items are always the hardest sell for superintendents.”

Considering system overhauls can easily be in the neighborhood of $2 million, going to the board with a request cannot be an easy task. For Richardson, the process took years, starting with a call to Vinchesi for an evaluation. With his report in hand, the board was approached.

“Once they read and comprehended the evaluation, it was obvious the need for a new system was there,” Richardson says. “This started a process of countless meetings and conversations that eventually lead to them approving the project.”

It took three years of work before any construction took place on the property and it ended up being the largest project in the club’s long history, which dates back to 1893.

It took three years of work before any construction took place on the property and it ended up being the largest project in the club’s long history, which dates back to 1893.

Adding to some possible difficulties getting a new irrigation system approved is the fact that the money spent isn’t likely to be recouped. According to Vinchesi, based solely on water savings, the return on investment is not there — courses should do it for improved playing conditions. If better conditions sell more rounds, memberships or associated real estate, then the cost-benefit becomes much more clear.

Redfern offers advice to superintendents considering this undertaking.

“Do your homework, then do it again,” he says. “Know your property and don’t get extravagant, but keep up with the times. You may not get another chance to do this again.”

He suggested showing your management dollars and how the course will save money by using a new system.

“My system had just been let go and there were way too many things to fix ... and at a very slow rate,” he says. “We were spending in excess of $50,000 to $60,0000 per year just in repairs trying to keep it together. With just the pump house renovations, heads replaced and a control system put in, I am spending $13,000 to $14,000, so you do the math on the payback. It works.”

Richardson stresses the importance of keeping accurate and complete records.

“Document, document, document,” he says. “Track all your irrigation expenses and, more importantly, track your labor. Make sure you have something tangible to show the board or owner.

“Make sure you track how many man hours you are spending on repairs and the man hours spent unnecessarily hand watering or setting up roller base sprinklers,” he added. “Do not forget to track your own hours. A big selling point here was that my time was being monopolized by the irrigation system or lack thereof.”

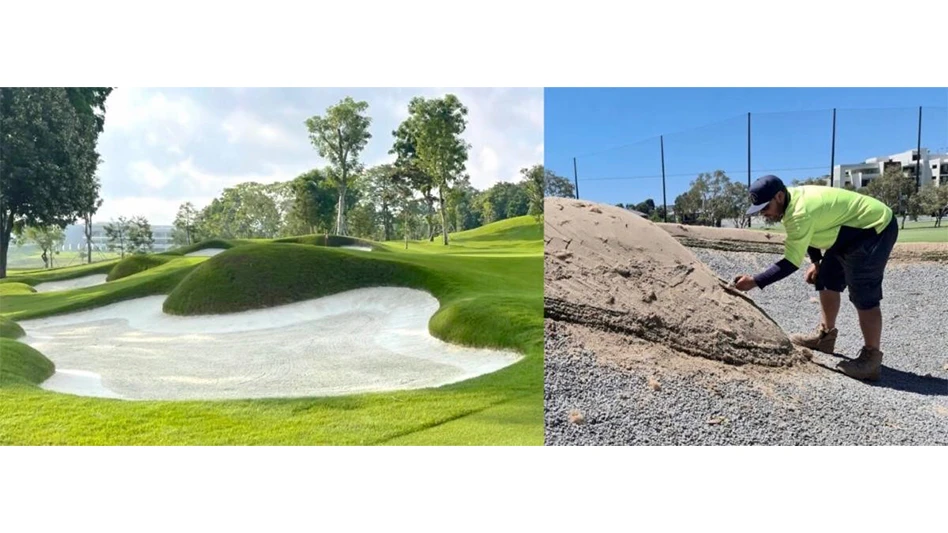

Richardson also suggested making a pile of the irrigation parts that have been replaced and taking a picture because “a visual aid is better than any words or document.”

Furthermore, he recommended visiting golf courses in the area that are in the middle of an installation. He visited four different sites with the club president, greens chairman and other prominent members.

“They were all amazed by the process and reported back to the membership on how little disruption there was,” he says. “This helped narrow the decision process into one that was solely financial.”

Lastly, hire a consultant.

“Brian steered me in the correct direction on multiple occasions,” Richardson says of Vinchesi. “Consultants have information that will be necessary to properly bid, permit and design the system. They can set realistic numbers and time tables.”

While Overbrook’s system was completed so late in the season that its membership really hasn’t had an opportunity to experience the improved conditions, Richardson claims success.

“The new system has allowed us to provide a firmer golf course, while managing disease and stress more effectively,” Richardson says. “According to the membership, the golf course has never looked or played better. The members were all amazed at the installation process, particularly with how small of a footprint the contractors, Leibold Irrigation Inc., had on the golf course and how clean and neat the installation process was in general.”

Rob Thomas is a Cleveland-based freelance writer and a frequent GCI contributor.

Explore the February 2012 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- Toro continues support of National Mayor’s Challenge for Water Conservation

- A different kind of long distance

- Golf Construction Conversations: Stephen Hope

- EnP welcomes new sales manager

- DLF opening centers in Oregon, Ontario

- Buffalo Turbine unveils battery-powered debris blower

- Beyond the Page 66: Keep looking up

- SePRO hires new technical specialist