Sights and sounds are often giveaways to a place of business. From sparks and the smoke of stick welders in a machine shop to the clanging and rattling of stanchions and drinking cups in a dairy barn, the familiarity of either place couldn’t be mistaken.

Sights and sounds are often giveaways to a place of business. From sparks and the smoke of stick welders in a machine shop to the clanging and rattling of stanchions and drinking cups in a dairy barn, the familiarity of either place couldn’t be mistaken.

So it is with a golf course shop – the smell of gas and diesel fuel, the unmistakable aroma of grass clippings and the sound of backlapping machines at work left no doubt about our places of business.

Maybe I should say, “was.” Stick welders are used, but less often than MIG and TIG welders, dairy barns are now usually free stalls with no stanchions or drinking cups and, as I have noticed in my travels around the Midwest, I don’t hear backlapping machines at work as often as I used to.

I always enjoyed the soothing sound of lapping compound on reel and knife, and was anxious to put really sharp mowers on our golf playing surfaces. Sometimes a stone would nick a reel or a buttress root would bend an edge of a bedknife, and the lapping machines came out for the repair. It started with a clickity-clack, but as the dinged-up reel or bedknife was matched, it became a rhythmic, almost harmonic sound. And it seemed backlapping was going on a couple days a week.

More than a few times I have wondered why backlapping seems less prevalent than I remember. I figured a lot of it out by thinking of the obvious. There was a time we mowed fairways with triplex greens mowers (we had the Jake GK 62s) and triplexes like the Ransomes Motor 180s. We had to use seven machines to get the job done – and we mowed fairways on a daily basis with the grass catchers. Why we ever did that is the subject for another conversation! We always had a couple of triplexes in reserve as backups or for tournaments and simultees. Triplex mowers at that time also cut greens and tees – four more machines. Roughs were nearly universally mowed with reel mowers – we had 10 gangs dedicated to that.

No wonder we backlapped so much! We also had five National triplexes to cut green and tee surrounds, and another triplex cut the intermediate rough/fairway collar. As with nearly everyone else, triplex cutters were used for green collars and approaches, too. It added up to nearly 70 reels at work on a given day, and they all required at least some attention during the season. Granted, not all reels were backlapped every week or even each month, but enough of them required close enough attention that we went through buckets of lapping compound to keep cutting edges sharp. I recall hearing about big clubs in the Chicago area that backlapped their greens mowers every day – it filled me with envy!

Let’s face it, no superintendent plans carefully and dutifully to execute a turf management program that could be diminished by something as simple as a dull mower. Mostly, you can rehab a dull edge fairly quickly with this low-technology procedure. That is why we did it. Backlapping also allowed for really close inspection of the cutter, and finding a loose reel bearing or oil leak at an early stage avoided problems. That was certainly helpful and helped justify the time commitment.

Let’s face it, no superintendent plans carefully and dutifully to execute a turf management program that could be diminished by something as simple as a dull mower. Mostly, you can rehab a dull edge fairly quickly with this low-technology procedure. That is why we did it. Backlapping also allowed for really close inspection of the cutter, and finding a loose reel bearing or oil leak at an early stage avoided problems. That was certainly helpful and helped justify the time commitment.

But it took a lot of time. Not all machines had the capability to run the reels in reverse while still in the frame of the mower. Units had to be removed, cleaned and attached to a Simplex or Foley backlapping machine. Some time was saved when you could leave them on the machine and let the power plant run them backwards. There were problems, but it was a fair trade-off.

Changes in equipment, culture and economy have diminished backlapping today relative to the 1970s and 1980s. Reel mowers have almost disappeared from our golf course roughs, taken over by high-tech rotaries that provide a superb finished turf product. The same is true for green and tee surrounds – rotaries are available that move quickly and mow well. Plant growth regulators have played an important role in the management of fine golf turf, and there is simply no need on most courses to mow fairways as often.

Rolling of putting surfaces has eliminated the need for double cutting for many superintendents. The result is fewer machines and fewer hours on them. Financial constraints in the past five to seven years have had a huge impact on how we manage courses. Many practices we would like to use are done less frequently; count backlapping among them. Prioritization puts it farther down the list of things to do.

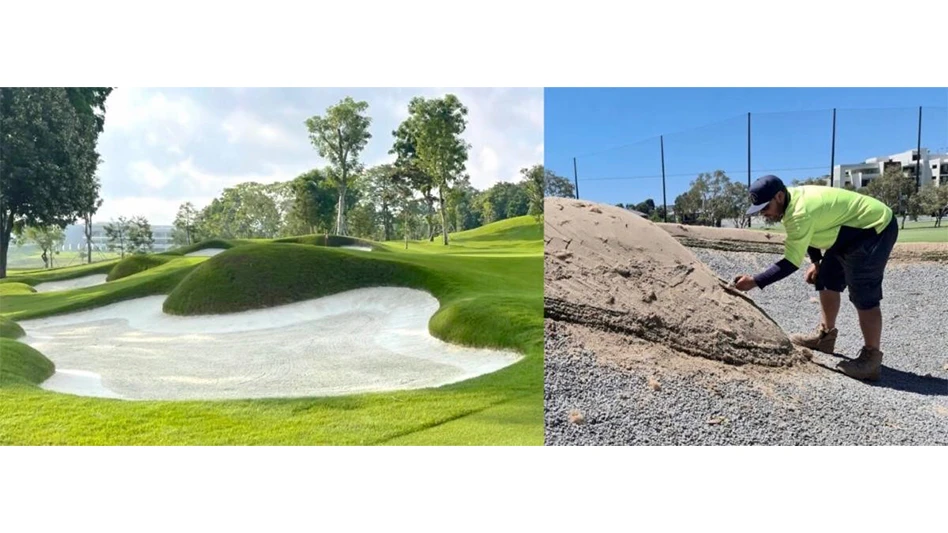

Sand topdressing as a cultural practice really took off in the 1970s, and despite the many different techniques superintendents use to move the sand down to around the plant crowns, dull mowers were always part of it. So was backlapping to get a sharp edge back. Jeff Thomas, veteran equipment manager at Pine Hills CC, says if it wasn’t for sand topdressing he could keep a sharp edge on today’s greens mowers most of the season with careful adjustment and an occasional, light face grind.

My instinct tells me that various practices like grooming, brooming and brushing also move sand to the surface and shorten the life of a sharp edge. It is the sand that causes the dull edge that creates the need to bring it back to sharp.

Almost everyone I talked to about this topic agreed that backlapping is used less than in years past. On a recent trip to the Twin Cities I stopped in at the Toro headquarters to get a manufacturer’s take on it. Scott Coffin, senior engineer of commercial products, pointed out that mower designers now use high-hardness materials – better steel for both reels and bedknives. “For some applications we are actually using tool steel because it holds an edge longer,” Scott says. To me, that spells less backlapping.

Not many have seen as much turf equipment as David Legg. He came to the U.S. from England to introduce Ransomes turf equipment to North America, spent years working from Jacobsen’s factory and now travels for a major Midwest Jake distributor. Legg echoes the significance of engineering improvements and adds that the sophistication and ease of on-board backlapping amplifies the notion we are backlapping less overall.

To Jeff Thomas’ point, we can see design improvements in cutting units that make it easier to adjust the reel and bedknife clearance, whether it’s light contact, 0.001-inch or 0.002-inch clearance. It takes less time, is more accurate and the units hold the adjustment better, resulting in a reduced need to backlap. Cliff Henning, the equipment manager at Kohler’s Whistling Straits, says newer and inexperienced turf equipment techs tend to backlap more until they acquire the feel and art of reel and bedknife adjustment. Toro’s Don Treu professes that “in a perfect world, there would be no backlapping.” But he quickly adds that there is no perfect world in our turf universe, and the cost of engineering such a feature would be prohibitive.

To Jeff Thomas’ point, we can see design improvements in cutting units that make it easier to adjust the reel and bedknife clearance, whether it’s light contact, 0.001-inch or 0.002-inch clearance. It takes less time, is more accurate and the units hold the adjustment better, resulting in a reduced need to backlap. Cliff Henning, the equipment manager at Kohler’s Whistling Straits, says newer and inexperienced turf equipment techs tend to backlap more until they acquire the feel and art of reel and bedknife adjustment. Toro’s Don Treu professes that “in a perfect world, there would be no backlapping.” But he quickly adds that there is no perfect world in our turf universe, and the cost of engineering such a feature would be prohibitive.

Even the individual blades of a reel have been milled to give a built-in relief to the blade so the land area (which contacts the bedknife) doesn’t get so wide, creating more friction and a shorter backlapping interval. Also, sometime notice how engineers have made it easier to remove a cutting unit from its carriage frame for backlapping when it is required.

Anyone my age can testify at length about the improvement of lapping compounds themselves and how they have shortened the time requirement to backlap a cutting unit. These improvements are often overlooked and minimized, although they shouldn’t.

Whenever you talk about contemporary backlapping, the topic that cannot be avoided is spin grinding. There is a sense that many cutting units that in the past were backlapped to a sharp edge are now put in a spin grinder and actually sharpened to the leading edge. I was telling someone about my past envy of a course that could actually backlap greens mowers every day, and he said there are golf courses that now spin grind those mowers every day because it is so easy. In fact, Whistling Straits’ Henning believes it is a safe bet that courses owning spin grinders do less backlapping simply because of the ease of spin grinding.

Foley United’s vice president Jim Letourneau emphasizes, “backlapping as a grinding process is gone, but as a preventative process it is alive and well!” He adds that if a reel blade is worn and little relief remains, lapping is ineffective and time-consuming – it should take five minutes or so to backlap a cutting unit to a sharp edge. Any more than that should require a trip to the grinder.

Potentially, there are as many different ways to keep an edge on a cutting unit as there are golf courses. Some only spin grind, some only backlap and there is every combination in between. Toro’s Don Treu has observed that backlapping is close to religion in some shops, and any more changes will come slowly. Letourneau attributes that, to some extent, to what he calls “training by tradition.” It is natural for some equipment managers to instruct subordinates in methods and techniques that have been successful for years, which doesn’t fully account for changes in technology. It is always hard to argue against a successful practice.

But in the final analysis, superintendents and their equipment managers figure out the best way to keep their cutting units sharp. Fortunately, they have both history and technology working to help make those decisions.

Monroe Miller is the author of “The Monroe Doctrine” and is a frequent GCI contributor.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

Explore the February 2012 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- Toro continues support of National Mayor’s Challenge for Water Conservation

- A different kind of long distance

- Golf Construction Conversations: Stephen Hope

- EnP welcomes new sales manager

- DLF opening centers in Oregon, Ontario

- Buffalo Turbine unveils battery-powered debris blower

- Beyond the Page 66: Keep looking up

- SePRO hires new technical specialist