Drag mat carrier

This 1993 Club Car Carryall-II Plus easily transports a 1-inch square steel drag mat or cocoa mat from green to green. It can also be fitted on the six other Carryalls. Two-inch angle iron, with the edges rounded-off where necessary for employee safety, was welded together from parts already in inventory. This lightweight carrier is mounted onto the dump bed using two 3/8-inch bolts on each side with flat and lock washers and wing nuts for a quick and easy installation and removal. The ends of the carrier are bent slightly upward to keep the drag mat in place, with the aid of bungee cords, during transport. Sand bags are put at the front of the dump bed as counterweights to keep the dump bed latches from stress from the weight of the drag mat and carrier. The carrier also has a gap intentionally left for the tailgate latches. It took less than three hours to design and build. Doug Marion, equipment manager, designed and built it at the Eagle Hills Golf Course in Eagle, Idaho. Jacob Sagasta is the new superintendent.

Power squeegees

These two motorized squeegees for greens offer different options for use during tournament play, instead of using manual push-type roller squeegees, and for much easier ice/slush/water removal during the winter and spring months.

Push-type

This 2013 John Deere 1200A Bunker Rake’s front plow is equipped with a custom-welded metal frame bolted to it. The squeegee “blade” was made from a rubber Snow Cat track, which is flexible at ¼-inch thick by 6-foot wide. Both ends of the squeegee are angled just like a floor-type push squeegee. The lever can distribute the amount of down pressure as the operator feels is appropriate. All the materials were scrap or in inventory. It cost about $10 for hardware and about five hours to design and build. Ben Wilmarth, former superintendent at Osprey Meadows at Tamarack (Idaho) Resort, designed and built it. Wilmarth is now the assistant superintendent at The Club at SpurWing in Meridian, Idaho.

Pull-type

The bunker rake was removed on this Cushman Groom Master and this custom-made squeegee was bolted to the hydraulic up and down framework. The 6-inch high by ¼-thick by 6-foot wide rubber belt is bolted to the recycled conduit, where the ends were bent inwards with a heat gun. One-inch chain, 1 ¼-inch square tubing and 2-inch angle iron were bolted to the conduit and then bolted to the bunker rake up and down mechanism. The operator can apply the correct amount of hydraulic down pressure as required. Also, a 40-pound “breaker bar” is laid on the 2-inch angle iron brackets for added weight. It took about 10 hours on and off to design and build. The materials were mostly recycled and the overall cost was less than $50. Brandon Crim, superintendent, and Sam Davis, irrigation and spray technician, at the Boise (Idaho) Ranch Golf Course designed and built it.

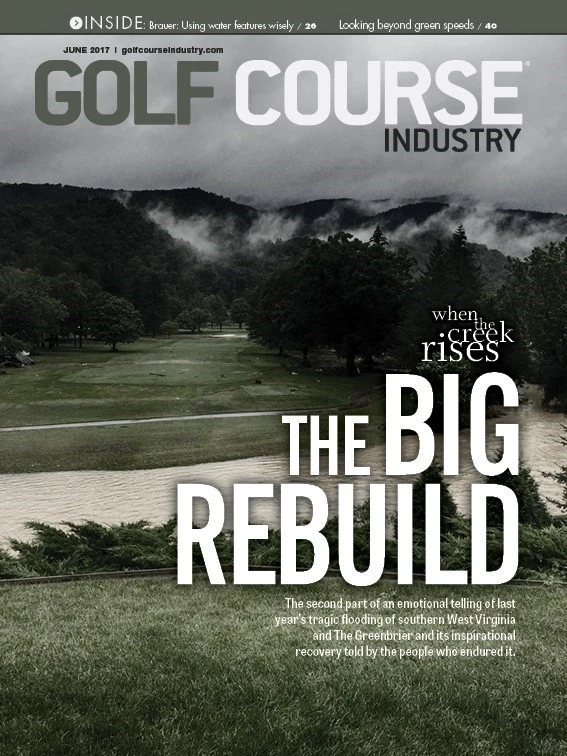

Explore the June 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- Carolinas GCSA raises nearly $300,000 for research

- Advanced Turf Solutions’ Scott Lund expands role

- South Carolina’s Tidewater Golf Club completes renovation project

- SePRO to host webinar on plant growth regulators

- Turfco introduces riding applicator

- From the publisher’s pen: The golf guilt trip

- Bob Farren lands Carolinas GCSA highest honor

- Architect Brian Curley breaks ground on new First Tee venue