Fleet managers hate hearing when one of their golf cars is dead on the fairway. Even though you’ve been consistent in charging the entire fleet every night, there’s always the occasional battery pack that shows it’s fully charged but never seems to last long.

Effectively predicting the runtime of a golf car’s battery pack starts with understanding the factors that affect its capacity. Manufacturers of deep-cycle lead-acid batteries usually list a battery’s capacity as runtime in minutes and amp-hour capacity. Both of these should give you a good estimate as to the amount of time in which a battery can deliver power under a specified load. While these ratings provide a good baseline for battery performance, there are other factors that can cause low runtimes that must be taken into account.

Time to Reach Full Capacity

It is important to know that new deep-cycle batteries do not perform to their rated runtimes immediately. New batteries often take anywhere from 25 to 125 cycles before reaching their full capacity. This is due to the active material on the battery plates not being fully converted until the battery has undergone multiple charge and discharge cycles. New batteries often perform at roughly 75 percent of their rated capacity, so expect performance to increase as the batteries are used.

Discharge Load

The discharge load of your car is also critical in determining the runtime of your batteries. Most golf cars have 48-volt motors that are supplied energy by 48-volt battery packs. In this configuration, the motor draws roughly 56 amps from the battery pack on average. For 36-volt cars, the motor draws roughly 75 amps on average. This is why most golf car batteries have 56A and 75A ratings listed on the label. When selecting a battery type for your fleet, pay attention to these ratings as they are the most relevant to golf car applications. When testing batteries, use the discharge load applicable to your system and compare the actual runtime to the ratings published on the battery.

Temperature

Deep-cycle battery performance is also affected by temperature. For every 20 degrees below 80 degrees, the battery loses 10 to 12 percent of its available capacity. Warmer temperatures above 80 have the opposite effect and increase battery performance, but at the cost of shortening battery life. In addition to battery performance, temperature can affect the charging performance of your fleet. Low temperatures can cause undercharging while high temperatures can cause overcharge conditions.

Knowing these tips and combining them with regular maintenance can dramatically increase the overall life span of the batteries and save your course money in the end. For more information on battery maintenance, capacity, and runtime ratings, visit www.usbattery.com.

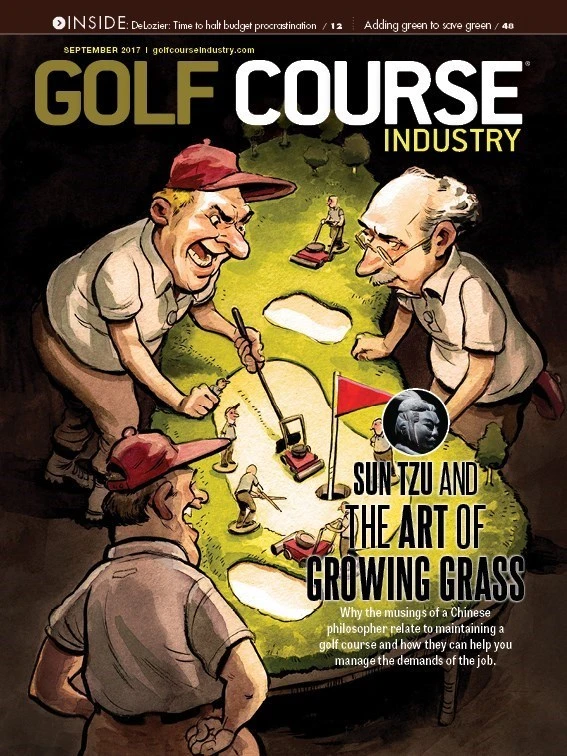

Explore the September 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- From the publisher’s pen: Conscientious of a bigger role

- Bernhard and Company partners with Laguna Golf Phuket

- Terre Blanche showcases environmental stewardship

- VIDEO: Introducing our December issue

- Bernhard and Company introduces Soil Scout

- Nu-Pipe donates to GCSAA Foundation’s Centennial Campaign

- GCSAA enhances golf course BMP tool

- Melrose leadership programs sending 18 to 2026 GCSAA Conference and Trade Show