No place in the country is as remote as Garden City, Kansas.

Well, no place that’s home to 25,000 or more residents is as remote as Garden City — at least in terms of its proximity to any other city home to 75,000 or more residents, and at least according to a 2018 study by the Malaria Atlas Project at Oxford University. There are smaller spots that require more travel time to the big city, but not many: Garden City is 224 miles west of Wichita, Kansas; 271 miles southeast of Colorado Springs, Colorado; 317 miles southeast of Denver; 379 miles southwest of Kansas City, Kansas; and, for good measure, 381 miles southwest of Kansas City, Missouri. If you are going to Garden City, someone or something is almost certainly pulling you there.

“We’re fairly isolated,” says Clay Payne, who is among the someones whose somethings seem to be pulling more and more people into Garden City — sometimes even by the foursome.

Payne is the superintendent at Buffalo Dunes Golf Course, a municipal facility tucked in among old fields donated to the city half a century ago by a feedyard operator named Earl Bookover Sr. and regularly ranked among the top public courses in the state and the country. Designed by Frank Hummel and fast approaching its 50th anniversary, it is also the site of an inventive, inclusive, inspiring, incredible and financially almost incomprehensible — but certainly not instant — renovation project.

Payne and his team recently started the second half of a six-year renovation highlighted by the removal of hundreds of Scotch pines planted throughout the 1980s, dozens of bunker renovations and 18 new greens. If handled conventionally with contractors and squeezed into a single offseason, the whole project could have hovered between $2 million and $3 million.

Instead, the first three years cost a reported $93,000.

Payne loves Buffalo Dunes, and he loved it long before becoming its superintendent in April 2017.

A big part of that love comes from a childhood in neighboring Cimarron. More love developed after his two years at Dismal River Golf Club in Mullen, Nebraska, and his five years at Ballyneal Golf Club in Hoylake, Colorado — both of which, like Buffalo Dunes, are spread out atop native sand. Back in 2017, he called Buffalo Dunes his favorite course in southwest Kansas, adding then that the course “already appeals to a broad base of golfers. I just want to be able to tweak some things to perhaps make it even better.”

“The tweaking started out small,” he says now. “We started shooting BBs. Now we’re firing cannonballs.”

During that first season, Payne and his team opened a handful of approaches, which sparked some fairway work, which inspired water conservation. “It just kept snowballing,” he says.

The renovation started in earnest later that first year, after Payne hired Mitch Chalkley — another Cimarron native — as his assistant superintendent but was unable to bring him on until after Chalkley wrapped up his coursework at Kansas State University in December. Payne proposed that Buffalo Dunes use what was earmarked as Chalkley’s salary to develop a master plan for the course — “with no intent of when we could use it,” Payne says. The City Commission quickly approved the reallocation, the master plan and some smaller projects. “‘What does $30,000 a year do for you?’” Payne remembers commission members asking him. “‘What can you do with that?’”

Plenty, as it turned out. With Chalkley on board the next season and working alongside Payne, fellow assistant superintendent Brock Walter, former superintendent Bob Bluml — who still mows most mornings and works 40-hour weeks after tending to the course from 1979 to 2007 — and equipment manager Mike Mathias, the team planned for the first stage by fielding requests for proposals from at least eight architects. They chose Todd Clark and Zach Varty, then developed a sod nursery on site to cultivate homegrown bentgrass and bluegrass. Clark schedules two or three visits every year. Varty normally arrives in Garden City around Labor Day and remains on site for the next six to eight weeks, driving from Minnesota and staying with the Paynes to reduce expenses. And the nursery, which cost about $2,500 to install, produces enough sod every year for at least three greens. Early on, Clark says he estimated the whole project could be whittled under $500,000 — with equipment rentals and Varty the biggest line items.

“The idea was to break the renovation down into small enough chunks that our crew can accomplish it each fall while also maintaining the golf course,” Payne says.

Each of the last three falls has started with the team ripping out greens and offering the old bentgrass to any local course or club that wants to pick it up. “Because we’re replacing it with the new variety of bentgrass from our nursery, there’s no need for us to have it anymore,” Payne says, adding that at least seven local courses have repurposed the old turf. “Then we’ll pull everything back, Zach will do all the shaping, and then it’s just a matter of regrassing.”

Because Buffalo Dunes has offered turf and trees to the local Lee Richardson Zoo, Valley View Cemetery and Sunset Memorial Gardens, city employees will chip in on laying sod for two greens. The third green is a citywide effort, with about 100 course and community members volunteering. “It gives them that sense of pride, “ Payne says. “And when they’re putting on it the next year, they have a story.”

Organizing that many maintenance newbies “is actually pretty easy once you supply doughnuts and coffee,” Payne says. He normally assigns one crew member to the nursery, where sod is rolled over PVC tubes and loaded onto a three-point trailer attachment designed by Mathias. A trio of trailers shuttle to the green, where the rest of the Buffalo Dunes team and the volunteers unload the sod. “It’s a lot easier to explain and keep track so guys who have never done it don’t have to worry,” says Walter.

The process has become streamlined over the last four years. “The first green took us four days,” Payne says. “Last year, No. 18 took us less than four hours.” The only real delay anymore is the time needed to haul sod from the nursery to the green.

“When you know every fall you’re going to go for 60 days, 80 days, working hard, and you’re going to do it for six years, that takes a lot to get motivated,” Clark says. “They have a unique process. Most clubs don’t have that time luxury. They’re not in a hurry. It works great.”

Chalkley — whose delayed arrival helped spark the master plan development — holds extra appreciation for being a part of every step. “I worked at a few courses and interned throughout college, but I never got to see a project out because I always had to go back to school in the fall,” he says. “It’s been really satisfying to be here and see the majority of this project finish out.”

“And to be able to come out and just see the changes that this course has had, to see everything be so ,” says Bryer Livermore, a Garden City native who worked at the zoo until joining the Buffalo Dunes team as an assistant superintendent earlier this year. “It’s still the same great atmosphere when I fell in love with golf, and now I’m out here every day.”

The renovation is far from finished. The fourth stage started the Tuesday before Labor Day and should wrap up by Halloween. Four old greens will remain, all of them scheduled to be resodded next year. The last planned year of the renovation, “we’ll just be grabbing some tees and bunkers that were left out here and there,” Payne says. “We want to get the greens done as quickly as possible because that’s what most people remember.”

More people are remembering those greens. In 2016, the last season before Payne and Walter arrived, Buffalo Dunes handled about 14,000 rounds. This year, the course is on pace to handle about 20,000 — and half of all rounds that are played by non-regulars are accounted for by golfers who traveled 100 miles or more. The course really is an attractive something.

And while the greens are the headliner, the most important thing, Payne says, is water conservation — as many as 20 acres of irrigated turf are being converted to non-irrigated native areas, which should save anywhere from 12 million to 20 million gallons of water annually. “It’s our job to make sure we can be as efficient with it as possible so that our kids and our kids’ kids can enjoy it and still have that natural resource,” Payne says.

Chalkley describes Buffalo Dunes as everybody’s hometown course. Walter attended high school just 40 minutes away and practiced on the course as a teenager. His son already plays the course regularly. Chalkley and Payne grew up 30 minutes away and played most of their high school tournaments on the course. Livermore has probably played it more than anybody on the team.

“It’s important for us to do it this way because we don’t believe that great golf should just be at expensive private clubs,” Payne says. “By doing it this way, we can keep the cost point down. You can come out and walk one of the best golf courses in the Midwest for $25.”

The renovation should wrap up some time around Halloween 2025. The opening day after that will mark the course’s 50th anniversary. No matter how isolated Garden City might be in the American West, it could feel like the center of the universe during that celebration.

“This is an example of what Small Town America is,” Payne says. “When you can get everyone rowing in the same direction, it’s not just a golf course project — it’s a Garden City project, it’s a western Kansas project. There are more resources than just hiring someone out. Enjoy the people you’re around.”

Explore the October 2023 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- From the publisher’s pen: Technology diffusion and turf

- Applications open for 2025 Syngenta Business Institute

- Smart Greens Episode 1: Welcome to the digital agronomy era

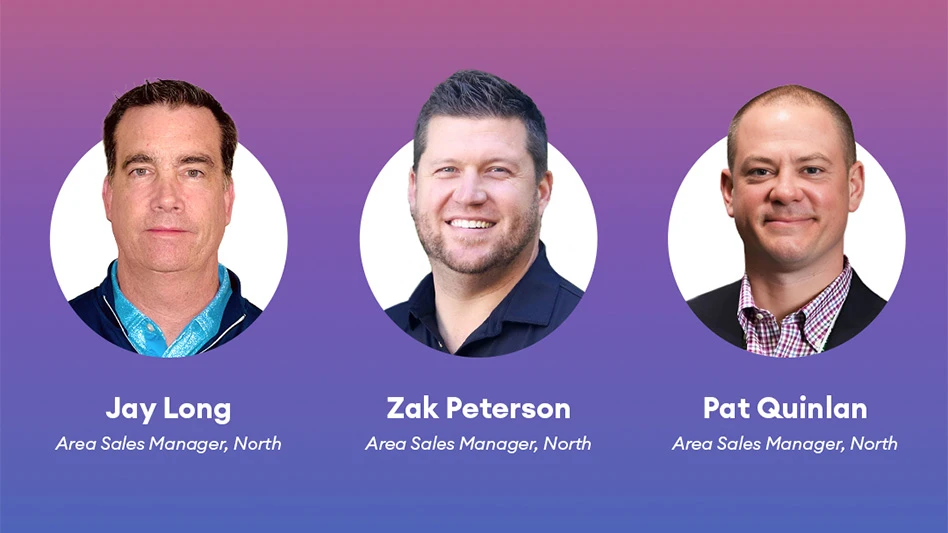

- PBI-Gordon promotes Jeff Marvin

- USGA investing $1 million into Western Pennsylvania public golf

- KemperSports taps new strategy EVP

- Audubon International marks Earth Day in growth mode

- Editor’s notebook: Do your part