Throughout the winter there are cosmic forces at work, as well as mice, intruders, well-meaning co-workers that may cause you to find the equipment to be in less than ready condition. The best thing to do is to avoid blame and just fix it.

Each year the average golf course makes a substantial investment in turf management chemicals, everything from pesticides to PGRs. For that investment to not be wasted, the chemicals must be applied in the right amount, in the right places, and at the right time. The operational status of the machinery used to properly apply those chemicals goes a long way toward determining if the money spent on each application does what it was intended to do. You want to make sure there is nothing that is going to interfere with proper application. You need your sprayers and spreaders in tip-top shape and for them to work flawlessly.

Here’s a rundown of the checks and tweaks you should make prior to calling this equipment back into service.

_fmt.png)

CHECKING THE SPRAY TRUCK

Battery. Tools needed: automotive battery tester, starting amp battery charger. Because there is a computer onboard, proper operation of the electrical system is a critical for this computer to work correctly. To identify electrical problems that have caused computer glitches in the past, I have added both a charging amp meter and a system volt meter to the dash board. A working battery is necessary to power up the vehicle and start the engine, but after six months being idle the battery will be weak or dead. Batteries typically last five years so there is a good chance that the battery will spring back to life. In case it does not, keep a spare battery on the bench in the shop. The battery life will be longer if it is charged slowly, so while the battery is charging slowly, I go to the next item, the tires.

_fmt.png)

Tires. Tools needed: chalk, tire pressure gauge, tire chuck, air hose and soapy water. Tires that are low or have gone flat might be able to be saved if they are aired up before trying to move the spray truck. Often a tire that has gone flat will re-seal itself when aired up. A quick check with soapy water will indicate if there are any leaks that need to be addressed. All the tires should be aired up to what the tires are rated for. Date and air pressure should be written on the tire with chalk. Each vehicle must be up on its tires so that it can be moved without damaging the tires. Expect some flats that can be aired up and some tires that will need to be replaced if the sidewall is cracked and leaking. The easiest way to move the equipment is under its own power.

_fmt.png)

_fmt.png)

Computer program. With the engine running, check battery amps and system voltage on the dash board gauges. If they are in the operating range, power up the spray control computer and scroll through the program settings to see that they are still there from last year. If they are, you are ready to go. If not, use your calibration cheat sheet (the settings written in the margins of the “settings page” in the operator’s manual) to re-enter the settings. A test run with water in the spray tank should show an application rate of 50 gallons per acre if everything is working properly.

_fmt.png)

SPREADERS

The average assortment of spreaders could include a tow behind wheel driven hopper, a front axle mounted electric spreader and a wheel driven walk behind. The baby dump truck that pulls the big spreader needs some of the same start of the season attention that the spray truck needs to get it ready for use. The spreader itself has only a few items to check.

Battery. Put one of the battery chargers on the battery while airing up the tires.

Tires. Air up the tires and note how well they hold air.

Fuel. Gasoline should be fresh smelling and the tank should be full.

Engine. Electronic fuel injection, starting fluid not needed here. The engine should start without any hesitation. Other “under the hood” fluids need to be checked: crank case oil, transmission oil, hydraulic oil, coolant level, brake fluid level all should be in operating range.

Spreader. While moving the spreader around, the wheels should drive the spinning disk. The pull cord that starts and stops the flow should be checked so that it is not worn or frayed.

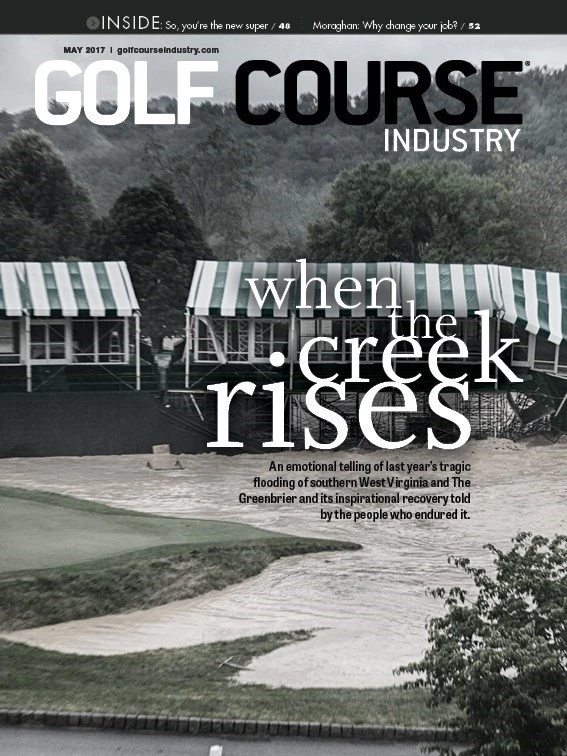

Explore the May 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- From the publisher’s pen: Conscientious of a bigger role

- Bernhard and Company partners with Laguna Golf Phuket

- Terre Blanche showcases environmental stewardship

- VIDEO: Introducing our December issue

- Bernhard and Company introduces Soil Scout

- Nu-Pipe donates to GCSAA Foundation’s Centennial Campaign

- GCSAA enhances golf course BMP tool

- Melrose leadership programs sending 18 to 2026 GCSAA Conference and Trade Show