For Paul Diegnau, CGCS, it’s the little things that separate a golf operation from the competition. Little things such as accessories: flags, sticks, cups, tee markers, bunker rakes, ball-mark repair tools, yardage markers, hazard stakes, ball washers, etc.

Diegnau, superintendent at the public 18-hole Keller Golf Course in Maplewood, Minn., views accessories as an important aspect of a golf course.

“If you have poor-quality accessories, it’s a reflection on your operation, and golfers notice those things,” he says. “They say things like, ‘Oh, you got new flagsticks. They look nice.’”

The parkland-style Keller Golf Course, which opened in 1929, is county owned and was renovated last in 1990. Another large-scale renovation might occur in the near future.

During the season, Diegnau’s staff consists of about 15 workers, varying by a couple people each season. His assistant, the mechanic and two foremen are union employees for the county, but Diegnau, who isn’t a union employee, and the mechanic are the only full-time employees of the course. The two foremen and the assistant work at ice rinks during the winter.

Because the course is a municipality, the budget is somewhat different than other golf course operations. Diegnau, who has been at Keller for the past 12 years as superintendent, has a $540,000 maintenance budget, which has been flat the past several years except for wages. Diegnau has no specific line item for accessories, but spends between $1,500 and $2,000 on them annually. Accessories include: flags, sticks, cups, tee markers, bunker rakes, ball-mark repair tools, ball washers, yardage markers, traffic control signage/markers and hazard stakes.

“We always have fresh flags every year,” he says. “We also paint the flagsticks every year, unless they’re too beat up, in which case we replace them.”

Accessories need to be durable to withstand the rigors of golfers’ behavior. The paint on the Par Aide satellite tee markers, which are composed of plastic resin, are taking a beating because golfers at Keller are hitting them with their clubs, Diegnau says. Keller’s clientele is a blue-collar crowd with a large percentage of single-digit handicappers with high expectations. Diegnau refurbishes these markers every year, but within several months, they’re beat up.

Theft also plays a part into the type of accessories Diegnau purchases. He uses checkered flags on the course without the course’s logo on them.

“We’re in a suburban setting, and if we put a logo on things, they tend to disappear,” he says.

Diegnau purchases as many accessories as he can from Minnesota-based Par Aide partly because he believes the company has high-quality products. He has also purchased accessories from Standard Golf and other companies who send him various product catalogs.

“I used to purchase flagsticks and bunker rakes from Standard Golf but have now switched to Par Aide because I like supporting local companies,” he says.

Diegnau prefers bunker rakes with fiberglass handles. He used to have a difficult time keeping the rakes looking nice after they sat in the sun all summer, so he put heat-shrink plastic covers on all the rake handles.

“Throw some Armor All on the heads, and they look new,” he says.

Generally, Diegnau purchases all accessories in February or early March before the season starts and as needed during the season. When it comes to flags and flagsticks, he purchases enough to replace those that are stolen or broken. Sometimes golfers and/or vandals throw the tee markers into the woods and ponds, so he keeps extras on hand in case that happens.

Diegnau also uses HIO cup cutters, which are hammered into the ground, not twisted, so it’s easier for smaller, lighter people to push into the ground.

Yet, there’s one accessory that eludes Diegnau: the perfect ball-mark repair tool. Currently, he’s using a product called the Klaw from Eagle One Golf Products, but it wears out quickly and is expensive to rebuild.

“I’ve tried most versions on the market and have yet to find the perfect one,” he says. “Par Aide has a new one, but we haven’t bought it yet. I’m looking for something that lasts a bit longer and doesn’t need to be repaired as often. More importantly, it has to do a good job of repairing ball marks on the green. Some of them don’t even do a good job of that.”

One of the jobs of the cup cutters at Keller is to repair ball marks.

“If the repair tool is three- or four-feet long, they’re more likely to repair more ball marks because they don’t have to bend over,” Diegnau says. “I’m always trying to minimize ball marks.” GCI

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

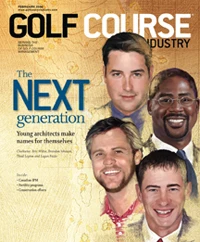

Explore the February 2008 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- Advanced Turf Solutions’ Scott Lund expands role

- South Carolina’s Tidewater Golf Club completes renovation project

- SePRO to host webinar on plant growth regulators

- Turfco introduces riding applicator

- From the publisher’s pen: The golf guilt trip

- Bob Farren lands Carolinas GCSA highest honor

- Architect Brian Curley breaks ground on new First Tee venue

- Turfco unveils new fairway topdresser and material handler