During a recent project interview, the greens committee asked what kind of construction I recommended for rebuilding its greens. Another architect had raised the idea of using a different greens construction method than the traditional U.S. Golf Association method most architects recommend. This had piqued the committee’s interest. But given the club’s finances, I don’t understand the curiosity.

If a course can afford it, it should invest in USGA greens. Considering the importance of greens to a course’s success, one can’t afford not to build them using the most recommended practice.

This is not to say that I’ve never recommended "California" or other greens construction, especially early in my career when budgets were tight. And in the current economy, I’m sure all aspects of golf course construction costs are being scrutinized, including whether USGA greens are necessary.

There are some key differences between USGA and California greens, and cost is just one. Typically, USGA greens cost $60,000 to $100,000 more than California greens on a 19-green renovation.

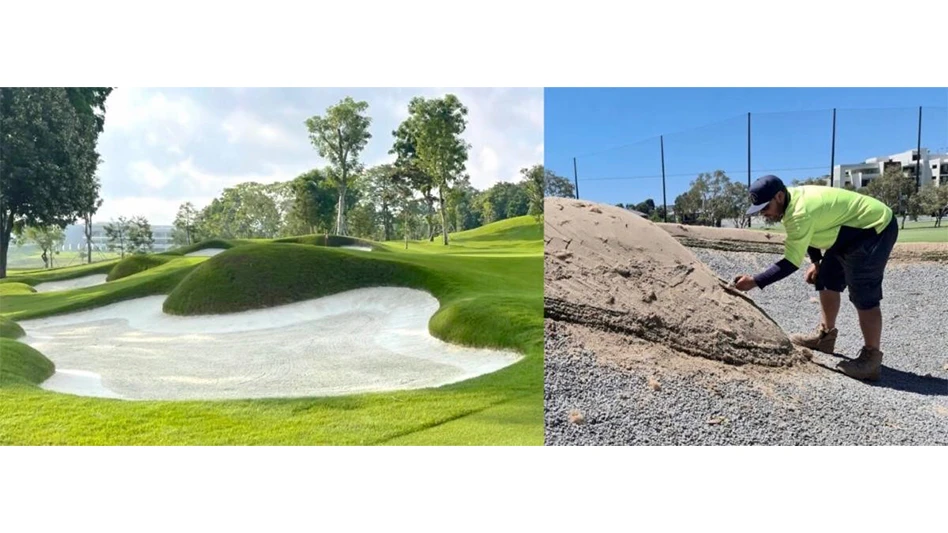

California greens also differ from USGA greens because they consist of 12 inches of pure sand placed directly on the sub-base. In contrast, the USGA method requires a 4-inch layer of gravel and, depending on material sizes, an intermediate layer of coarse sand to keep root-zone sand from filtering into the gravel. Both methods call for a herringbone tile pattern to drain water from the green cavity.

In spite of these differences, I’ve recommended California greens with success under the following six conditions:

1. The superintendent understands them and wants them;

2. Water quality is poor, and the pure sand moves it through the profile (although newer research shows that USGA greens drain faster because of the gravel layer and do well even with poor water quality);

3. Weather is relatively temperate, and a qualified superintendent can grow grass under less-than-optimum conditions;

4. Where native sands naturally have porous characteristics;

5. When the owner absolutely needs to save money; and

6. Where long-term success isn’t critical to the owners.

Still, constructing California greens isn’t the only option for saving money. There are a host of modified USGA procedures, although the USGA may deny this. One typical shortcut on lower-budget jobs is rototilling organic amendments instead of mixing off-site or using sand that doesn’t conform to recommendations. In either case, there’s a risk of eliminating the benefits the USGA method was intended to create.

When construction cost is an issue, one way for superintendents to sell the additional expense of a USGA green is the insurance sales technique of breaking down that cost into a daily increment. This makes the cost seem smaller. Say, throughout the expected 15- to 20-year life span of those greens, the additional cost translates to less than $1 per green per day.

Another plus is that USGA recommendations have always been based on extensive research and have been modified many times since being introduced in 1968. On the other hand, university researchers developed the California method shortly after the original USGA green. The California financial crises prevented further research funds for golf greens, while USGA recommendations were revised earlier this year.

"The 2004 guidelines are the result of more than 100 people worldwide evaluating all aspects of greens construction," says Jim Moore, USGA construction education director. "We are happy with the approach taken, and it incorporates both real-world expertise of architects, contractors and superintendents, and academic evaluation gleaned from turfgrass research over the last two years."

The revised USGA recommendations have come full circle to their original intentions of incorporating local sands to build practical greens inexpensively and minimize compaction, while using fertilizer and irrigation technologies to replace nutrients and water lost more easily through a sand profile. As a result, the cost differences between USGA and other methods are narrowing.

The cost of building USGA greens has increased for years. As the USGA refined the sand characteristics through more research, there was an unintended consequence. Adherence to the sand particle charts – which were intended as a first step to determine if a type of sand might have suitable characteristics – meant that sand choices narrowed too much.

A few high-profile lawsuits, such as one in which the contractor wasn’t paid because greens drained 0.1 inch per hour less than the USGA guidelines, scared architects, superintendents and soil testing and agronomy consultants into using more expensive sands than necessary to keep within USGA guidelines. And the expense of sand isn’t just a one-time cost. After selecting imported sand for construction, superintendents must continue to top dress with that sand or risk creating layers in the greens.

Luckily, the newest USGA greens material recommendations and increased options for sand, tile, organics and percolation rates allow more ways for greens reconstruction to meet recommendations. Typically, I recommend USGA greens and then working with the project superintendent to acquire local, site-specific materials.

Still, for all the science that goes into the basic USGA green, every course needs a specific green construction method. Superintendents who have been in regions for a long time have done their own research and may have a lot of information in their heads. One might call it "feel" or intuition, but superintendents with such experience should make the final call on minor tweaks to get the greens just right. There are many great greens not built exactly to USGA specs – a tribute to the skills of the superintendent and a nod to the notion that there’s still some art, and not all science, to the job of producing great greens. GCN

Jeffrey D. Brauer is a licensed golf course architect and president of Golfscapes, a golf course design firm in Arlington, Texas. Brauer, a past president of the American Society of Golf Course Architects, can be reached at jeff@jeffreydbrauer.com.

Explore the June 2004 Issue

Check out more from this issue and find your next story to read.

Latest from Golf Course Industry

- Toro continues support of National Mayor’s Challenge for Water Conservation

- A different kind of long distance

- Golf Construction Conversations: Stephen Hope

- EnP welcomes new sales manager

- DLF opening centers in Oregon, Ontario

- Buffalo Turbine unveils battery-powered debris blower

- Beyond the Page 66: Keep looking up

- SePRO hires new technical specialist